3D printing is changing the way prosthetic hands and arms are made. In the past, getting a prosthetic limb was expensive, time-consuming, and often limited by outdated manufacturing methods. Today, 3D printing has made it possible to create high-quality prosthetics at a fraction of the cost, making them more accessible to people who need them.

For many upper limb amputees, the biggest challenge has always been affordability and customization. Traditional prosthetics can cost thousands of dollars and may not always be designed to fit an individual’s unique needs. But with 3D printing, prosthetic hands and arms can now be made faster, lighter, and more tailored to the user.

The Traditional Challenges of Upper Limb Prosthetics

For decades, the process of getting a prosthetic hand or arm followed a standard path.

A prosthetist would take a mold of the residual limb, design a socket, and then fit a prosthetic device made from expensive materials like carbon fiber or silicone.

While these methods produced functional prosthetics, they also had several challenges.

One major issue was cost. Traditional prosthetics often range from ₹3,00,000 to ₹10,00,000 or more, depending on the level of technology involved.

This makes them unaffordable for many people, especially in developing countries where access to financial support is limited.

Even if insurance covers part of the cost, many families still struggle to afford the best prosthetic options.

Another challenge was time. Creating a custom prosthetic hand could take weeks or even months.

Every step, from making the mold to testing the final fit, required multiple visits to the prosthetist.

If the prosthetic didn’t fit perfectly, additional adjustments were needed, further delaying the process.

Fit and comfort were also common concerns. Since traditional prosthetics were designed using standardized methods, they didn’t always accommodate the unique shape and size of every residual limb.

This often led to discomfort, pressure sores, or limited functionality.

Finally, repairs and replacements were expensive and difficult. If a part broke, getting a replacement could be costly, and users often had to wait for imported parts.

For children, who outgrow their prosthetics quickly, frequent replacements meant even higher costs.

These challenges left many amputees without access to functional prosthetic hands. But 3D printing is changing that.

How 3D Printing Is Making Prosthetics More Affordable

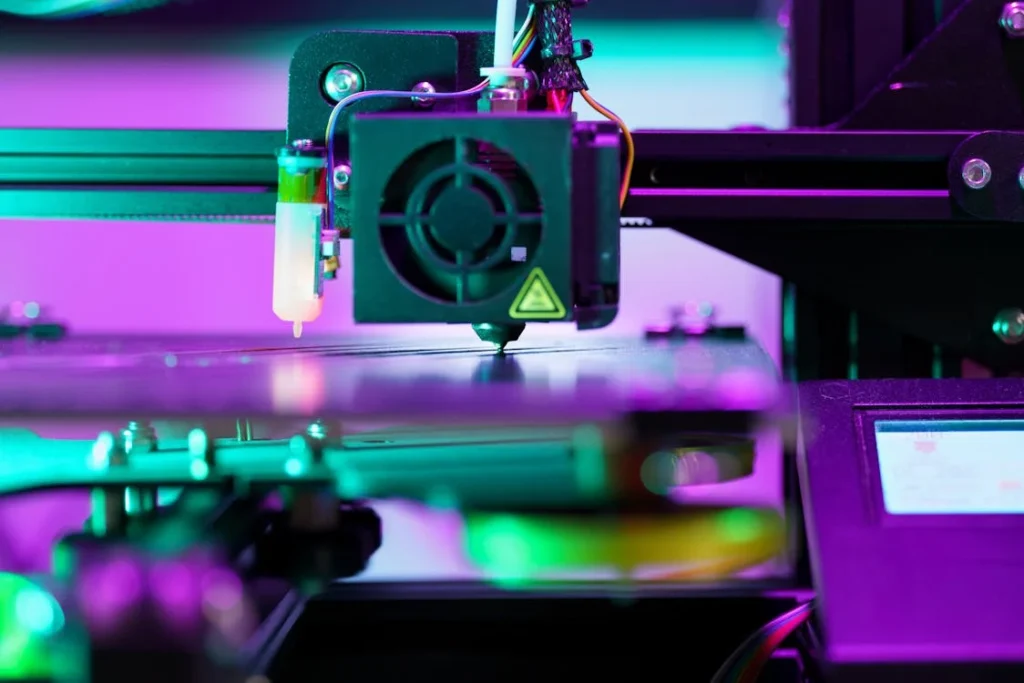

The biggest advantage of 3D printing is that it lowers costs without compromising quality.

Instead of relying on expensive materials and complex manufacturing processes, 3D-printed prosthetics use lightweight yet durable materials like biocompatible plastics and flexible polymers.

These materials are significantly cheaper than traditional prosthetic components.

Because 3D printing allows for on-demand production, there’s no need for large factories or mass production.

A prosthetic hand can be designed and printed in just a few days, drastically reducing both manufacturing costs and delivery times.

This makes it possible for users to receive high-quality prosthetics at a fraction of the cost of traditional models.

Customization and Personalization with 3D Printing

One of the biggest challenges with traditional prosthetics is the lack of personalization.

Since every residual limb is unique, a prosthetic must be designed to fit comfortably while allowing for natural movement. This is where 3D printing offers a major advantage.

Creating a Perfect Fit

A well-fitting prosthetic is crucial for comfort and functionality. In the past, making a custom socket involved molding materials around the residual limb, which was time-consuming and sometimes inaccurate.

With 3D scanning technology, the shape of the limb can now be captured digitally, ensuring precise measurements.

These scans are used to design a socket that fits perfectly, eliminating pressure points and discomfort.

Since 3D-printed prosthetics are designed digitally, they can also be easily modified if needed.

If a user experiences changes in limb shape due to muscle growth or weight fluctuations, adjustments can be made without having to create a completely new prosthetic.

This flexibility makes 3D printing an ideal solution for people who need frequent modifications.

Lightweight and Ergonomic Designs

Many traditional prosthetic hands and arms are heavy, making them uncomfortable to wear for long periods.

3D printing allows for the creation of lightweight yet durable prosthetics that reduce strain on the user’s body.

Materials like high-strength plastics and carbon-reinforced polymers provide durability without adding unnecessary weight.

Ergonomics also play a key role in usability. A well-designed prosthetic should allow for natural arm movements, minimizing effort while maximizing control.

Through digital modeling, 3D-printed prosthetics can be shaped to ensure they match the user’s natural biomechanics, improving comfort and ease of use.

Aesthetic and Functional Customization

Beyond fit and comfort, 3D printing allows users to personalize their prosthetics in ways that were not possible before.

Prosthetic hands and arms can now be customized in terms of color, texture, and even design patterns.

Some users prefer a natural skin tone, while others choose bold colors or artistic designs to reflect their personality.

Functionality can also be tailored to individual needs. Some users require a prosthetic that focuses on grip strength for tasks like lifting objects, while others need one designed for delicate tasks such as typing or using a smartphone.

With 3D printing, different grip patterns and joint movements can be programmed into the prosthetic, making it more adaptable to a person’s lifestyle.

At Robobionics, we use advanced 3D modeling and printing techniques to create prosthetics that are not only functional but also designed to match the specific needs and preferences of each user.

This ensures that every prosthetic we produce is as unique as the person wearing it.

Faster Production and Easy Repairs with 3D Printing

One of the biggest limitations of traditional prosthetic manufacturing is the time it takes to create and deliver a fully functional device.

With multiple stages involved—molding, casting, assembling, and testing—the entire process can take weeks or even months.

3D printing is drastically reducing this time, allowing users to receive their prosthetics much faster.

Rapid Production and Delivery

Unlike conventional prosthetic manufacturing, which involves manual labor and complex fabrication, 3D printing automates much of the process.

Once a digital design is finalized, a prosthetic hand or arm can be printed within hours or days rather than weeks.

This is particularly beneficial for users who need a prosthetic urgently or those who live in remote areas where access to prosthetists is limited.

Since 3D-printed prosthetics do not require large-scale production facilities, they can be manufactured in localized clinics or even in mobile units equipped with 3D printers.

This decentralized production model allows for faster service, reducing wait times and ensuring that people receive their prosthetics sooner.

At Robobionics, we have streamlined our 3D-printing process to ensure that users get their prosthetic hands as quickly as possible without compromising quality.

By using digital designs and automated printing, we have significantly cut down the time required for fitment and delivery.

Easy and Affordable Repairs

Traditional prosthetic hands and arms are often difficult to repair. If a component breaks or wears out, the replacement part may be expensive or take weeks to arrive, especially if it needs to be imported.

With 3D printing, replacement parts can be produced quickly and affordably, reducing downtime for the user.

Instead of replacing an entire prosthetic, specific parts—such as fingers, joints, or sockets—can be reprinted and replaced with minimal cost and effort.

This not only extends the lifespan of the prosthetic but also makes maintenance much more accessible.

Users no longer have to worry about long repair periods or high costs associated with fixing their devices.

For children who outgrow their prosthetics frequently, 3D printing provides an efficient solution.

Instead of purchasing a completely new prosthetic, modifications can be made to accommodate their growth.

New parts can be printed to adjust the size, making it easier and more affordable for young users to continue using their prosthetics comfortably.

On-Demand Customization and Upgrades

Another advantage of 3D printing is the ability to upgrade prosthetics without having to create an entirely new device.

As technology improves, new features such as better grip strength, additional articulation, or even sensory feedback systems can be integrated into existing prosthetics.

Instead of waiting years for a new model, users can simply replace or upgrade specific components.

At Robobionics, we prioritize making our 3D-printed prosthetics adaptable and easy to repair.

By ensuring that parts are readily available and can be customized as needed, we help users maintain their prosthetics for longer periods while keeping costs low.

The Role of 3D Printing in Expanding Access to Prosthetics

For many people, the biggest barrier to getting a prosthetic hand or arm is accessibility.

Traditional prosthetics are often expensive, difficult to obtain, and require multiple visits to specialized clinics.

This creates challenges for individuals in remote or underserved areas who may not have access to the right medical professionals.

3D printing is changing this by making prosthetics more widely available, regardless of location or financial background.

Bridging the Gap for Rural and Low-Income Communities

In many parts of the world, including India, access to high-quality prosthetic care is limited to major cities.

People in rural areas often have to travel long distances to reach a clinic, and the cost of the prosthetic itself can be out of reach.

With 3D printing, prosthetics can be produced locally at a much lower cost, reducing the financial and logistical burden on users.

Community-based organizations and healthcare providers are now using portable 3D-printing setups to produce prosthetics in remote regions.

This means that individuals no longer have to wait for months or spend large sums of money to receive a functional prosthetic hand.

Instead, they can have a customized, 3D-printed device delivered to them in a fraction of the time and cost.

At Robobionics, we believe that everyone deserves access to high-quality prosthetics, no matter where they live.

Our 3D-printing approach ensures that users in both urban and rural areas can receive affordable, well-fitted prosthetic hands without the delays and expenses of traditional manufacturing.

Helping Children and Growing Individuals

Children who need prosthetics face a unique challenge—growth.

A prosthetic that fits a child today may become too small within a year, requiring frequent replacements that many families cannot afford.

With traditional prosthetic production, each new device is expensive and time-consuming to make.

3D printing offers an ideal solution for children, as new prosthetics can be produced quickly and affordably.

Instead of investing in a costly new device each time a child outgrows their prosthetic, adjustments can be made by simply reprinting specific parts to accommodate their growth.

This ensures that children always have a properly fitted prosthetic without placing a financial strain on their families.

Additionally, 3D-printed prosthetics can be designed with lightweight materials that are easier for children to use.

The ability to customize colors and designs also makes prosthetics more engaging, helping young users feel more confident and excited about wearing their devices.

Partnering with Nonprofits and Healthcare Initiatives

Many organizations around the world are leveraging 3D printing to provide prosthetics as part of humanitarian efforts.

Nonprofits, hospitals, and social enterprises are working together to bring low-cost prosthetics to individuals who would otherwise go without.

By eliminating the high costs associated with traditional prosthetics, these initiatives are making a significant impact in improving the lives of upper limb amputees.

Robobionics actively collaborates with healthcare providers, rehabilitation centers, and NGOs to expand the reach of our 3D-printed prosthetic solutions.

Our goal is to ensure that every person who needs a prosthetic can access one, regardless of financial status or geographic location.

By embracing 3D printing technology, we are making upper limb prosthetics more accessible, practical, and life-changing.

The Future of 3D-Printed Upper Limb Prosthetics

3D printing has already made a significant impact on the prosthetics industry, but the technology is still evolving.

Researchers, engineers, and medical professionals are continuously working on new ways to improve the design, function, and accessibility of 3D-printed prosthetic hands and arms.

The future holds even greater possibilities, with advancements that could make prosthetics more lifelike, responsive, and affordable than ever before.

Integration of Artificial Intelligence and Smart Technology

One of the most exciting developments in prosthetics is the integration of artificial intelligence (AI) and smart sensors.

Currently, myoelectric prosthetic hands use muscle signals to control movement, but they require training and can sometimes be difficult to operate.

AI-driven prosthetics, however, are being developed to learn from the user’s movements and adapt in real-time, making control more intuitive.

Future prosthetic hands could feature machine learning algorithms that anticipate a user’s intended movement based on previous actions.

This would allow the prosthetic to respond faster and more naturally, reducing the need for excessive muscle training.

Some advanced models are even being designed with pattern recognition systems that can differentiate between different muscle signals, enabling finer control over finger movements.

Another key area of innovation is haptic feedback, which aims to bring a sense of touch to prosthetic hands.

Researchers are developing sensors that can detect pressure and temperature, sending signals to the user’s nervous system to create a sensation of feeling.

This would allow prosthetic users to better judge the force of their grip, making delicate tasks like holding a fragile object much easier.

Stronger, More Flexible Materials for Enhanced Durability

While current 3D-printed prosthetics are lightweight and functional, future advancements in materials will make them even stronger and more resilient.

Scientists are experimenting with carbon fiber-infused filaments, biodegradable polymers, and flexible yet durable composites to create prosthetics that can withstand more wear and tear while remaining comfortable.

One of the main concerns with prosthetics is long-term durability.

Traditional prosthetics made from metal and high-density plastic can last many years, but they are expensive and difficult to modify.

Future 3D-printed prosthetics will use next-generation materials that combine strength with flexibility, ensuring that the prosthetic remains both durable and adaptable to different activities.

Additionally, some researchers are exploring self-repairing materials, which could automatically fix small cracks or wear over time.

This would significantly reduce the need for frequent repairs or replacements, making prosthetics even more cost-effective in the long run.

More Advanced Customization and Personalization

Personalization has always been one of the biggest advantages of 3D printing, and future advancements will take this even further.

Prosthetic users will soon be able to fully design their own hands and arms using digital customization tools.

This means they could choose different grip patterns, adjust the level of stiffness in each joint, and even add decorative elements to make their prosthetic match their personal style.

Another possibility is the mass customization of prosthetic designs, where users can download pre-designed prosthetic templates and modify them according to their needs.

This would allow individuals to receive a new prosthetic in just a few days, eliminating long waiting periods.

At Robobionics, we are constantly exploring new ways to push the boundaries of 3D-printed prosthetics.

Our research and development team is focused on making prosthetics even more responsive, comfortable, and accessible.

As new technology emerges, we will continue to integrate the latest advancements to ensure that our prosthetic users benefit from the most innovative solutions available.

The Impact of 3D Printing on Pediatric Prosthetics

Children who need prosthetic hands or arms face a unique set of challenges.

Unlike adults, they are constantly growing, which means their prosthetics must be replaced or adjusted frequently.

Traditional prosthetic solutions are not only expensive but also time-consuming to manufacture, making it difficult for many families to keep up with their child’s needs.

3D printing is solving this problem by providing affordable, adaptable, and child-friendly prosthetics that grow with the user.

Addressing the Cost Barrier for Growing Children

One of the biggest challenges for families with children who need prosthetics is cost.

A high-quality traditional prosthetic can cost several lakhs of rupees, and children outgrow them every few years.

In some cases, families have to choose between keeping an outdated prosthetic or going without one entirely.

With 3D printing, the cost of producing a prosthetic is drastically lower, making it more feasible for families to replace or upgrade their child’s prosthetic as they grow.

Since 3D-printed prosthetics can be produced on demand, parents don’t have to worry about long waiting periods or expensive custom solutions.

Instead, new prosthetics can be printed affordably whenever a child outgrows their previous one.

Designing Lightweight and Playful Prosthetics

Children are naturally active, and a prosthetic must be lightweight, comfortable, and durable to keep up with their daily movements.

Traditional prosthetics can sometimes be too heavy for small children, making them uncomfortable to wear for long periods.

3D printing allows for lighter materials that do not compromise on strength, ensuring that a child can use their prosthetic comfortably throughout the day.

Beyond functionality, 3D printing also introduces a level of personalization that makes prosthetics fun for children.

Many kids feel self-conscious about using a prosthetic, but when they have the option to customize their device with bright colors, superhero designs, or even glow-in-the-dark elements, they often feel more confident and excited to use it.

At Robobionics, we encourage children to be part of the design process, allowing them to choose colors, patterns, and even shapes that make their prosthetic feel more like an extension of their personality.

By transforming the prosthetic into something fun and engaging, we help children feel empowered rather than different.

Adapting Prosthetics for Different Stages of Growth

Children not only grow in size but also develop new motor skills over time.

A prosthetic that works well for a toddler may not be suitable for a child who is learning more advanced hand movements.

3D printing allows for modular prosthetic designs that can be easily adjusted to match a child’s developing abilities.

For younger children, simpler mechanical hands with basic grip functions are often ideal, while older children may benefit from more advanced myoelectric prosthetics that respond to muscle signals.

Instead of requiring an entirely new prosthetic at each stage, 3D printing makes it possible to upgrade individual parts—such as adding better grip control or introducing new joint movements—without needing a complete replacement.

Robobionics is committed to making affordable, adaptable prosthetics for children, ensuring that they can enjoy the same freedom and independence as their peers.

Our 3D-printing technology allows us to create prosthetics that grow with the child, offering an innovative and cost-effective solution for families.

Conclusion

3D printing is transforming the world of upper limb prosthetics, making them more affordable, customizable, and accessible than ever before. By reducing production costs and enabling rapid prototyping, this technology ensures that more people—especially those in underserved communities—can access high-quality prosthetic solutions.

Beyond affordability, 3D printing allows for lightweight, ergonomic, and highly personalized designs, ensuring a comfortable fit for users of all ages. Children, in particular, benefit from prosthetics that grow with them, reducing the financial burden on families. Advances in AI, smart sensors, and durable materials are further improving prosthetic functionality, paving the way for more intuitive and lifelike movement.

At Robobionics, we are committed to pushing the boundaries of 3D-printed prosthetic innovation. By combining cutting-edge technology with a user-first approach, we are making prosthetic hands and arms more accessible, functional, and empowering. If you or a loved one is looking for an advanced yet affordable prosthetic solution, explore our 3D-printed Grippy™ today and take the first step toward renewed independence!