The world of prosthetics is transforming in ways we could only imagine a few decades ago. For those living with limb loss, these changes bring new hope and opportunities. At the heart of this transformation is 3D printing—a revolutionary technology that’s making prosthetics more accessible, affordable, and customizable than ever before.

Gone are the days when prosthetics were heavy, expensive, and hard to adapt to. With 3D printing, we’re seeing a shift toward lighter, highly personalized, and cost-effective designs.

Whether it’s a child needing a hand that grows with them or an athlete requiring a limb that supports intense activities, 3D printing opens doors to innovations we couldn’t dream of before.

Breaking Barriers in Prosthetic Design with 3D Printing

3D printing, also known as additive manufacturing, has disrupted traditional prosthetic design in several key ways. At its core, 3D printing works by layering material to create objects from a digital model. This process eliminates the need for heavy machinery or expensive molds, which have been the cornerstone of traditional prosthetics.

Personalization at Its Best

One of the biggest advantages of 3D printing in prosthetics is its ability to create custom designs for each individual. No two people have the same body shape, size, or needs, and prosthetics must reflect that.

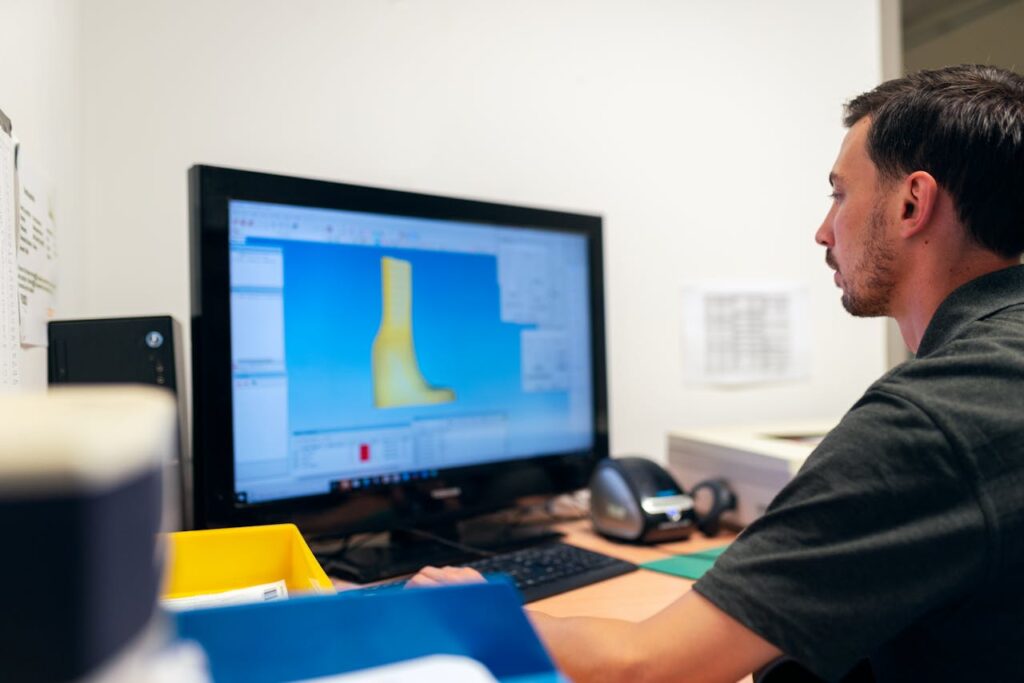

Using a 3D scanner, a patient’s limb can be mapped with incredible accuracy. This data is used to create a perfectly fitting prosthetic that feels like a natural extension of the body.

For example, children who are still growing can benefit greatly from this customization. Instead of waiting years for a new prosthetic due to the high cost of traditional methods, a 3D-printed version can be updated more frequently and affordably.

Lightweight and Comfortable

Comfort is a critical factor in prosthetics. Traditional prosthetics are often made from heavy materials like metal, which can cause fatigue and discomfort over time. 3D printing allows for the use of lightweight materials such as specialized plastics, making prosthetics more comfortable to wear throughout the day.

Additionally, 3D-printed designs can incorporate ventilation holes and other ergonomic features that improve the user experience. This focus on comfort encourages users to wear their prosthetics consistently, improving their quality of life.

Reducing Costs, Increasing Access

Cost is a significant barrier for many people who need prosthetics. Traditional manufacturing methods require skilled labor, expensive materials, and complex equipment. All of this drives up the price, making prosthetics inaccessible for many.

3D printing dramatically reduces these costs by cutting down on material waste and automating much of the production process. A 3D printer only uses the exact amount of material needed to build the prosthetic, which minimizes waste. The lower cost of production makes prosthetics more accessible to people in low-income communities or developing countries.

Speeding Up the Process

With traditional methods, creating a prosthetic can take weeks or even months. 3D printing speeds up this process significantly. Once the design is finalized, the prosthetic can be printed in a matter of hours or days.

This rapid production timeline is especially valuable for patients who have suffered recent injuries and need prosthetics quickly to regain their independence.

Enhancing Functionality Through Design Innovation

3D printing doesn’t just make prosthetics faster and cheaper; it also allows for incredible design innovations that improve functionality.

Advanced Joint Mobility

For prosthetic hands, fingers, and legs, movement is everything. 3D printing makes it possible to design complex joint mechanisms that mimic the natural range of motion.

This level of precision wasn’t always possible with traditional methods. Today, users can grip objects, type on keyboards, and even perform delicate tasks with their 3D-printed prosthetics.

Bionic Integration

Combining 3D printing with advanced technologies like sensors and actuators has paved the way for bionic prosthetics. These devices can respond to muscle signals or brain activity, allowing users to control them as they would a natural limb.

This seamless integration between the body and prosthetic offers a level of independence that was once unimaginable.

Aesthetic Appeal

In addition to functionality, aesthetics matter. Many users want their prosthetics to look natural or reflect their personality.

3D printing makes it easy to customize the appearance of a prosthetic, whether it’s adding a realistic skin tone or a unique design. Some users even choose vibrant colors and patterns that make their prosthetics a bold statement of individuality.

Transforming Rehabilitation with 3D-Printed Prosthetics

The journey to adapting to a prosthetic doesn’t end with fitting. Rehabilitation plays a crucial role in helping users integrate their new limb into daily life. Thanks to 3D printing, this process has also seen remarkable advancements.

Faster Prototyping for Trials

Before finalizing a prosthetic, it’s important to ensure it works perfectly for the user. 3D printing enables the creation of multiple prototypes quickly and at a lower cost. Users can try different designs to find the one that suits their mobility and lifestyle needs best.

This iterative process was much slower and more expensive with traditional methods, often leaving users stuck with suboptimal prosthetics.

Gamified Rehabilitation Tools

3D printing isn’t limited to creating the prosthetics themselves. It can also be used to develop rehabilitation tools. For instance, custom-designed grips, toys, or exercise equipment can be printed to help users practice movements in a fun and engaging way.

At Robobionics, we’ve incorporated gamified home-based rehabilitation programs, making the process smoother and less intimidating for users of all ages.

Supporting Unique Requirements

Every prosthetic user has unique rehabilitation needs. A child may need tools to improve hand-eye coordination, while an athlete might focus on building strength and flexibility.

3D printing makes it possible to create personalized rehabilitation aids tailored to these specific requirements.

Creating Modular Rehabilitation Tools

With 3D printing, businesses can design and produce modular rehabilitation tools that adapt to users’ changing needs. For example:

Start users with simple tools to build foundational skills and gradually increase complexity. For instance, a series of gripping tools with varying resistance can help users improve dexterity and strength. Print interchangeable parts for tools, such as handles or weights, allowing therapists to tailor exercises for individual users.

Partner with occupational therapists to identify key rehabilitation goals and create toolkits that clinics can use to accelerate patient progress. Offer these as part of a subscription model for recurring revenue.

Designing Rehabilitation Games

Gamification enhances motivation during rehabilitation. 3D-printed prosthetics can integrate with game-based tools that make therapy engaging and fun. Businesses can design:

Lightweight 3D-printed bands or add-ons can track user movements during exercises. These can connect to mobile apps, providing real-time feedback and progress tracking. Develop VR-compatible 3D-printed accessories, such as handles or buttons, to simulate real-world scenarios. Users can practice gripping, pushing, or pulling in a controlled environment.

Collaborate with software developers to build interactive apps or VR systems that integrate with your prosthetics. Offer bundled packages to clinics or end-users to stand out in the market.

On-Demand Production for Personalized Rehab Tools

Every user’s rehabilitation journey is unique, and 3D printing makes on-demand customization seamless. Instead of mass-producing generic tools, businesses can offer:

Allow clinics to request specific tools based on individual patients’ needs. For instance, if a patient struggles with buttoning shirts, a specialized assistive tool can be designed and printed. As a user progresses, tools can be modified to match their development, ensuring continued engagement and effectiveness.

Set up a streamlined digital workflow where clinics can upload patient data, specify requirements, and receive custom tools quickly. Use this model to build a strong relationship with rehab centers.

Empowering Home-Based Rehabilitation

Many users prefer rehabilitating in the comfort of their homes. Businesses can cater to this growing demand by developing 3D-printed rehabilitation kits that users can use independently. These kits might include:

Print tools with QR codes that link to video tutorials or step-by-step guides, ensuring proper use at home. Design lightweight and space-saving tools that fit easily into a home environment.

Provide subscription-based delivery of updated tools and guides as users advance. Market these directly to end-users or through clinics as add-on products.

Collaborating with Clinics for Prototyping and Training

Prosthetic businesses can build strong partnerships with rehabilitation clinics by offering prototyping services and training resources. Use 3D printing to:

Involve therapists in the design process to ensure tools meet practical rehabilitation needs. Provide 3D-printed demo kits and training materials to help clinics incorporate your products effectively into therapy programs.

Host workshops or webinars for clinics, demonstrating how 3D-printed tools can enhance their rehabilitation programs. Offer discounts or incentives for early adopters.

Making Sustainability a Priority

Another remarkable benefit of 3D printing in prosthetics is its contribution to sustainability. The traditional manufacturing of prosthetics often involves wasteful processes that use more material than necessary. 3D printing flips this approach by being inherently eco-friendly.

Circular Economy Through Material Reusability

3D printing offers a pathway to implementing a circular economy by reusing and recycling materials. Unlike traditional manufacturing, where excess material often becomes waste, 3D printing allows leftover materials from one project to be repurposed for future use.

Businesses can set up systems to collect unused or discarded 3D-printed parts and recycle them into new prosthetics or tools. Switching to biodegradable or compostable filaments ensures even discarded materials break down in an eco-friendly manner.

Partner with material suppliers to offer eco-friendly filaments as a standard option. Promote your use of sustainable materials as a key differentiator in your marketing efforts.

Localized Manufacturing for Reduced Carbon Footprint

By setting up localized 3D printing hubs, businesses can minimize transportation-related emissions. Prosthetics can be printed closer to the point of need, reducing the environmental impact of shipping and packaging.

Establish small-scale 3D printing units in regional clinics or urban centers, enabling faster and greener delivery. Instead of stocking inventory that may go unused, businesses can print prosthetics as orders come in, avoiding overproduction and waste.

Build partnerships with rehabilitation centers or clinics to house 3D printers on-site. Offer training programs to staff, empowering them to handle basic printing and adjustments for users locally.

Eco-Friendly Design Innovations

3D printing allows businesses to incorporate eco-conscious designs that optimize material use and energy efficiency. This includes prosthetics that are:

Internal lattice structures can reduce material consumption without compromising strength or durability. Design prosthetics that serve multiple purposes, reducing the need for additional accessories or devices.

Work with engineers to develop templates for low-material, high-strength designs. Highlight these designs as part of your sustainability pledge to attract environmentally conscious customers.

Collaborating with Eco-Driven Partners

The sustainability movement thrives on collaboration. Partnering with other eco-conscious organizations or startups can help businesses innovate faster and adopt best practices.

Work with suppliers specializing in recycled or renewable filaments to reduce the environmental impact of your supply chain. Partner with organizations focused on sustainable healthcare to deliver eco-friendly prosthetics to underserved communities.

Establish a “green label” certification for your prosthetics, verified by third-party organizations, to validate your commitment to sustainability. Use this certification as a selling point to eco-conscious buyers.

Energy Efficiency in Production

While 3D printing is generally more energy-efficient than traditional methods, there’s still room to optimize. By focusing on energy conservation during the printing process, businesses can further minimize their environmental footprint.

Invest in advanced 3D printers with lower power consumption and optimized heating elements. Print multiple parts in a single session to reduce the energy required for multiple individual prints.

Regularly audit your printing facilities to ensure energy efficiency. Promote these efforts in your corporate social responsibility (CSR) reports to build trust with environmentally conscious stakeholders.

Building Brand Loyalty Through Sustainability

Sustainability isn’t just a strategy; it’s a powerful way to build loyalty and trust with customers. Consumers are increasingly aligning themselves with brands that reflect their values, and showcasing a strong commitment to the environment can enhance your reputation.

Share stories about how your eco-friendly prosthetics are making a difference—not just for users but for the planet. Host events or social media challenges that encourage users to participate in sustainable practices, such as recycling programs or tree-planting drives linked to prosthetic sales.

Create a monthly or quarterly newsletter dedicated to sustainability updates. Use this as a platform to connect with customers and showcase your achievements in eco-conscious manufacturing.

The Future of Prosthetics with 3D Printing

As technology continues to evolve, the potential for 3D printing in prosthetics is boundless. Advancements in materials science, artificial intelligence, and robotics will only enhance what’s possible.

Smart Prosthetics: Fusing Intelligence with Design

The next frontier in prosthetics combines 3D printing with artificial intelligence (AI) and sensor technology. These advancements promise a new level of functionality, enabling prosthetics to think, adapt, and respond.

AI-powered prosthetics will adapt in real time to users’ activities, such as increasing grip strength for carrying objects or improving flexibility for athletic activities. Embedded sensors can monitor vital metrics like muscle engagement and skin temperature, enhancing user comfort and safety.

Collaborate with AI and sensor developers to create modular smart prosthetics that users can upgrade as technology evolves. Launch prototypes targeting niche markets, such as athletes or heavy laborers, who need advanced functionalities. Build a subscription-based model for software updates and AI upgrades, keeping users engaged and ensuring their devices remain cutting-edge.

Distributed Manufacturing: Local Solutions for Global Needs

Decentralized 3D printing is poised to revolutionize prosthetic manufacturing, reducing logistical challenges and expanding access to underserved regions.

Establish regional printing facilities to deliver prosthetics faster while minimizing transportation costs and carbon footprints. Provide clinics with access to a cloud-based platform featuring customizable prosthetic designs, enabling on-demand printing at local facilities.

Partner with clinics and rehabilitation centers to deploy small-scale 3D printing setups, creating a network of localized production hubs. Offer licensing agreements for your digital design library, generating recurring revenue. Develop turnkey printing kits for clinics, complete with hardware, software, and training programs to facilitate rapid adoption.

Next-Generation Materials: Redefining Strength and Sustainability

Material innovation is paving the way for prosthetics that are stronger, lighter, and more sustainable. Future prosthetics will incorporate advanced materials to balance durability with user comfort.

Prosthetics made from polymers that can repair minor damages automatically, reducing the need for frequent replacements. Combining lightweight plastics with flexible metals to create prosthetics that offer enhanced performance in various conditions.

Invest in partnerships with material scientists to explore cutting-edge composites and polymers for your product line. Launch a sustainability-focused range using biodegradable or recycled materials to capture eco-conscious markets.

Use sustainability certifications and eco-friendly branding to differentiate your products, appealing to both individual users and institutional buyers.

Customization at Scale: Merging Function with Personalization

The ability to personalize prosthetics beyond functionality will become a defining factor in user satisfaction. Future designs will empower users to express themselves while meeting their practical needs. Offer removable covers with patterns, colors, or textures that users can swap based on mood or occasion. Tailor designs to resonate with cultural preferences, ensuring prosthetics are both functional and meaningful.

Develop an online customization tool where users can design their prosthetics, choosing colors, patterns, and add-ons. Create limited-edition collaborations with designers or brands to attract users seeking unique, stylish options.

Partner with e-commerce platforms or create your own to sell aesthetic accessories and prosthetic upgrades, generating a new revenue stream.

Digital Twin Technology: Precision Through Virtual Prototyping

Digital twin technology—virtual replicas of prosthetics linked to real-world data—is revolutionizing design and maintenance processes. Virtual testing of prosthetic designs in real-world scenarios can reduce production costs and improve product reliability. Digital twins can monitor wear and tear, notifying users or clinics when maintenance is required before issues arise.

Integrate digital twin capabilities into your product lifecycle management systems, enhancing efficiency and user satisfaction. Offer clinics predictive maintenance services as part of long-term care packages. Develop a platform where users can access real-time performance data for their prosthetics, creating transparency and fostering trust.

Expanding Market Access with Modular Prosthetics

Modularity is key to affordability and scalability. By creating prosthetics that can evolve with users’ needs, businesses can reach new markets and improve customer retention.

Offer a basic model that users can enhance with add-ons like advanced joints or sensors as their needs grow. Design models specific to regional requirements, such as climate resistance or cultural aesthetics.

Focus on emerging markets where traditional prosthetics are prohibitively expensive, positioning modular solutions as accessible alternatives. Establish flexible financing options like rent-to-own programs to increase adoption rates. Bundle modular prosthetics with user training and support services, ensuring users maximize the value of their investment.

Conclusion

3D printing has truly revolutionized the field of prosthetics, breaking down barriers that once limited access, affordability, and personalization. By blending innovation with empathy, this technology is giving people with limb loss more than just a prosthetic—it’s giving them independence, dignity, and a renewed sense of purpose.

For those who have lived with the challenges of traditional prosthetics, 3D printing offers a brighter, more hopeful future. The ability to design prosthetics that are tailored to each individual’s needs—whether functional, aesthetic, or both—is transforming lives across the globe.

At Robobionics, we’re proud to be part of this revolution. Our flagship product, Grippy™, exemplifies the best of what 3D printing can offer: lightweight, ergonomic, and easy-to-use prosthetics that feel like a natural extension of the body. With innovations like gamified rehabilitation and NABL-certified quality, we’re making prosthetics not just tools, but partners in everyday life.