Technology is changing the way we live, and for people with disabilities, innovations in 3D printing are creating new possibilities. Traditional assistive devices—such as prosthetic limbs, orthopedic supports, and mobility aids—have been expensive and difficult to customize. But now, 3D printing is making assistive devices more affordable, accessible, and tailored to individual needs.

With the ability to create lightweight, durable, and highly personalized solutions, 3D printing is revolutionizing the way assistive devices are made. It is reducing costs, speeding up production, and allowing users to receive customized devices that fit their bodies and lifestyles perfectly. But does this mean 3D printing is the future of assistive technology? Can it truly replace traditional methods?

How 3D Printing is Changing Assistive Devices

Traditional assistive devices have long been made using complex manufacturing processes that involve multiple steps, high costs, and long waiting periods.

A prosthetic limb, for example, often requires extensive measurements, molding, and adjustments before a final version is ready. This can take weeks or even months, making it difficult for people who need urgent solutions.

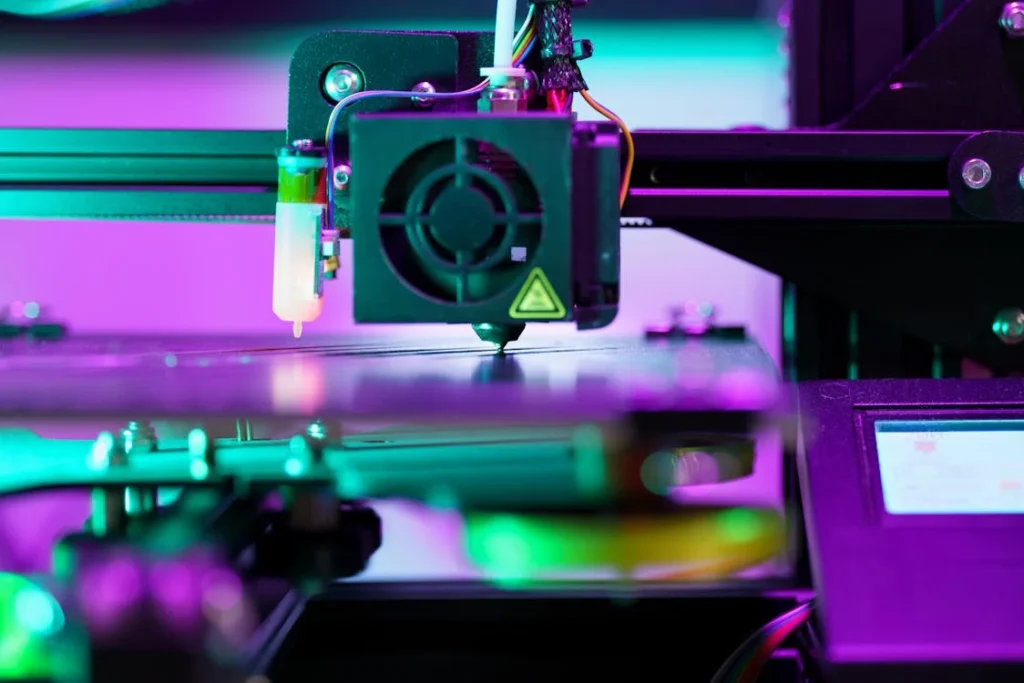

3D printing is changing this entirely. Instead of relying on heavy machinery and time-consuming processes, assistive devices can now be designed on a computer and printed within hours or days.

This shift is making assistive technology more accessible to people who previously could not afford or easily obtain it.

Personalized for Every User

One of the biggest advantages of 3D printing is its ability to create fully customized solutions. No two people are the same—whether it’s the shape of their limbs, their range of movement, or their daily activities.

Traditional devices often come in standard sizes that may not perfectly fit everyone, leading to discomfort and limited usability.

With 3D printing, assistive devices can be designed to match a person’s exact measurements. Scanning technology allows for precise digital models to be created, ensuring a perfect fit.

Whether it’s a prosthetic hand that matches the user’s grip strength or an orthopedic brace that provides the right level of support, 3D printing allows for unmatched personalization.

Reducing Costs and Making Devices More Affordable

One of the biggest challenges people face when seeking assistive devices is the high cost. Traditional prosthetics, for example, can cost thousands of dollars, putting them out of reach for many.

Children who need prosthetic limbs often require multiple replacements as they grow, making the costs even higher.

3D printing dramatically reduces production expenses. The materials used in 3D-printed devices—such as lightweight plastics and resins—are often much cheaper than the metals and specialized components used in traditional devices.

Since 3D printing also eliminates the need for expensive molds and specialized manufacturing tools, it makes high-quality assistive devices more affordable for a larger number of people.

Faster Production and Delivery

For many individuals, waiting for an assistive device can be frustrating, especially if it means limited mobility or discomfort in the meantime. Traditional manufacturing methods often involve multiple stages, each adding to the total production time.

3D printing speeds up this process significantly. Once a digital design is created, it can be printed in just a few hours. This means that people who need new prosthetic limbs, braces, or other assistive devices can receive them much faster.

This is especially important in regions where access to specialized medical facilities is limited.

Overcoming Challenges in 3D-Printed Assistive Devices

While 3D printing has transformed the way assistive devices are made, there are still challenges that must be addressed before it becomes the standard method of production.

The technology has come a long way, but for widespread adoption, it must overcome issues related to durability, regulations, and accessibility.

Strength and Durability Concerns

Assistive devices need to be strong enough to handle daily use. Traditional prosthetics, for example, are often made from metals and high-strength materials that can withstand wear and tear over time.

Many 3D-printed devices, however, are made from plastic-based materials, which may not always provide the same level of durability.

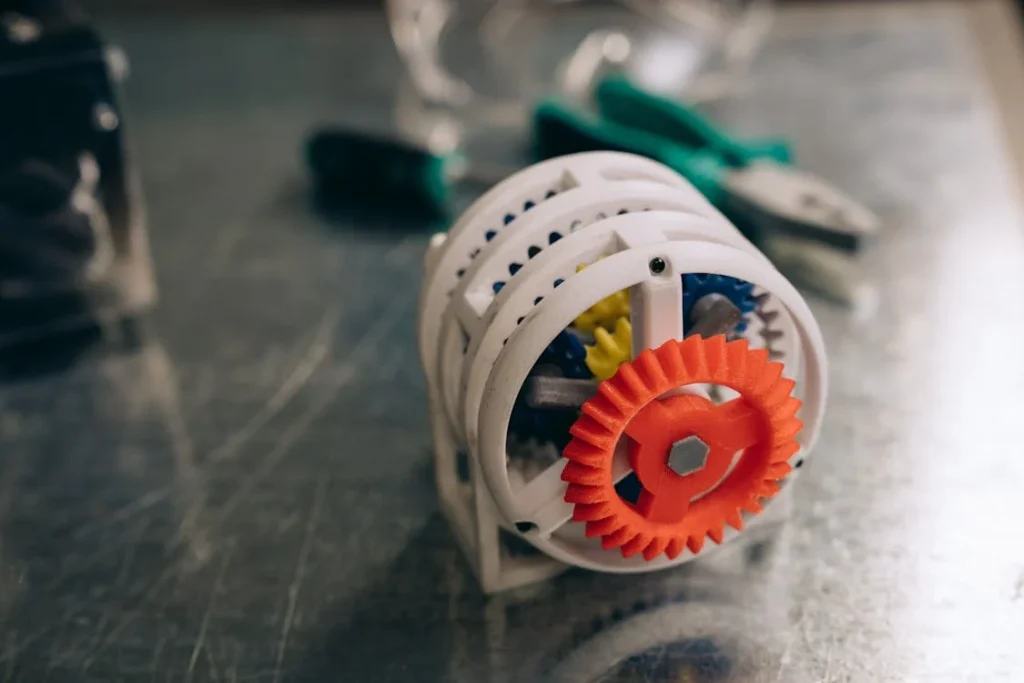

Advancements in 3D printing materials are addressing this issue. Newer printing technologies now allow for stronger, more flexible materials that mimic the durability of traditional devices.

High-performance filaments like carbon fiber-reinforced plastics and bio-compatible resins are being developed to make 3D-printed prosthetics more reliable and long-lasting.

However, not all 3D-printed devices are built to last for years. Some designs are intended as temporary or low-cost solutions, especially in disaster relief situations or for children who will soon outgrow their devices.

Finding the right balance between affordability and long-term usability remains a challenge that researchers and manufacturers continue to work on.

Regulation and Safety Standards

Medical devices must meet strict safety and quality standards to ensure they are safe for users. Traditional assistive devices go through rigorous testing and approvals before they can be used by the public.

Since 3D-printed assistive devices are still relatively new, global regulations have not yet fully caught up with the technology.

In some countries, there are concerns about whether 3D-printed devices can provide the same level of safety as their traditionally manufactured counterparts.

Without standardized guidelines, the quality of 3D-printed assistive devices can vary widely. Some products may be high-quality and reliable, while others could be poorly designed and unsafe for extended use.

To address this, researchers and manufacturers are working closely with regulatory bodies to establish testing protocols and safety measures.

Some 3D-printed prosthetic devices have already received approvals in certain regions, paving the way for more standardized production in the future.

Accessibility of 3D Printing Technology

While 3D printing has made assistive devices more affordable, not everyone has access to this technology. Many developing countries and rural areas still lack the necessary infrastructure, including high-quality 3D printers, skilled technicians, and reliable material supplies.

Efforts are being made to expand access to 3D printing for assistive devices. Organizations and non-profits are setting up workshops and training programs to help local communities learn how to design and print custom prosthetics and mobility aids.

In some areas, mobile 3D printing units are being used to bring this technology to people who would otherwise not have access to it.

As 3D printing continues to advance, the goal is to make the technology more widespread so that assistive devices can be created quickly and affordably wherever they are needed.

The Future of 3D-Printed Assistive Devices

The progress made in 3D printing for assistive devices is only the beginning. As technology continues to evolve, new advancements are expected to make these devices even more functional, durable, and accessible.

From improved materials to AI-driven customization, the future of 3D-printed assistive technology looks promising.

Advancements in 3D Printing Materials

One of the biggest limitations of early 3D-printed assistive devices was the materials used. Basic plastic filaments, while lightweight and affordable, did not always offer the durability or flexibility needed for long-term use.

However, researchers and manufacturers are developing advanced materials that will significantly enhance the quality of 3D-printed devices.

New bio-compatible materials, including flexible polymers and reinforced composites, are being designed to mimic the properties of human tissue and bone.

These materials not only provide better strength but also improve comfort, making prosthetics and orthopedic supports feel more natural.

Additionally, developments in metal 3D printing are making it possible to create stronger, lightweight prosthetics that rival traditional metal-based solutions.

AI and Machine Learning for Customization

Customization is one of the biggest advantages of 3D printing, but future innovations will take it even further. With artificial intelligence (AI) and machine learning, assistive devices can be designed with even greater precision.

AI-powered software can analyze a user’s movements, muscle strength, and daily activities to create a perfectly tailored prosthetic or support device.

This level of customization means that instead of a one-size-fits-all approach, assistive devices will be built to match the unique needs of each individual.

AI can also continuously adjust designs based on user feedback, ensuring that future versions of the device improve over time.

Integration of Smart Technology

The future of 3D-printed assistive devices is not just about better materials and customization—it’s also about adding smart technology.

Some prosthetic limbs are already being equipped with sensors that allow users to control movement with their thoughts or muscle signals. These “bionic” devices are expected to become even more advanced as technology improves.

Wearable assistive devices, such as 3D-printed exoskeletons, are being developed to help people with mobility impairments walk again. These lightweight, customized supports provide additional strength to muscles and joints, allowing users to regain movement with minimal effort.

Even everyday assistive tools, such as grips for holding objects or adaptive utensils, are being designed with smart features.

Some 3D-printed devices are now incorporating Bluetooth connectivity, enabling users to control their environment—such as adjusting the grip strength of a prosthetic hand or operating smart home devices with a simple movement.

The Role of 3D Printing in Disaster Relief and Remote Areas

One of the most exciting aspects of 3D-printed assistive devices is their potential to provide immediate solutions in emergency situations.

In war zones, natural disaster areas, and remote villages where medical facilities are scarce, 3D printing can create life-changing assistive devices on demand.

Instead of waiting weeks or months for prosthetic limbs to be shipped, local communities can use 3D printers to manufacture them on-site.

Some humanitarian organizations have already begun using portable 3D printing units to provide prosthetic limbs to those who have lost limbs in conflicts or accidents.

Additionally, telemedicine and digital health platforms are making it possible for doctors and engineers to design assistive devices remotely and send the digital files to be printed anywhere in the world.

This means that someone in a rural village could receive a perfectly fitted prosthetic limb, even if the nearest specialist is thousands of miles away.

The Role of 3D Printing in Pediatric Assistive Devices

Children with disabilities often face unique challenges when it comes to assistive devices. As they grow, their needs change, requiring frequent adjustments or replacements of prosthetics, orthotic supports, and mobility aids.

Traditional devices, however, are expensive and not always designed to accommodate rapid growth. 3D printing is emerging as a game-changer in pediatric assistive technology, offering solutions that are not only cost-effective but also fun, customizable, and child-friendly.

Growing with the Child

One of the biggest struggles parents face when obtaining assistive devices for their children is outgrowing them too quickly.

A prosthetic limb or orthopedic brace that fits perfectly one year may become too small the next, forcing families to go through the lengthy and costly process of getting a new one.

3D printing allows for quick modifications and reprinting as a child grows. Instead of waiting months for a new prosthetic or support device, parents and healthcare providers can simply adjust the digital design and print a new version within days.

This ensures that children always have devices that fit properly, improving comfort and mobility while reducing costs for families.

Customization for Comfort and Engagement

Children are naturally active and playful, and they often want assistive devices that reflect their personalities. Traditional prosthetic limbs or orthopedic braces can sometimes feel clinical or impersonal, which may make children reluctant to use them.

With 3D printing, kids can have prosthetics in their favorite colors, decorated with fun designs, or even shaped like superhero arms or robotic hands.

These personalized touches help make assistive devices feel less like medical equipment and more like an exciting part of their lives. When children feel excited about their devices, they are more likely to use them confidently.

Lightweight and Easy to Use

Many traditional prosthetics and mobility aids are designed for adults and then scaled down for children. Unfortunately, this can result in devices that are still too heavy, uncomfortable, or difficult for a child to use.

3D-printed pediatric assistive devices can be designed with lightweight materials that are strong but easy for children to wear and control. Since they are made specifically for a child’s body and activity level, they provide better support without unnecessary bulk or weight.

Affordability and Access for Families

The cost of assistive devices for children can be overwhelming, especially for families who do not have access to insurance or government support. Since 3D-printed devices are significantly cheaper to produce, they provide a much-needed affordable option for parents.

Non-profit organizations and research institutions are already working to make 3D-printed pediatric prosthetics widely available, especially in underserved regions.

Some programs even provide free 3D-printed prosthetics to children in need, ensuring that no child is left without the tools they need to thrive.

3D Printing and the Future of Bionic Prosthetics

While 3D-printed assistive devices have already made a significant impact in providing affordable and customized solutions, the next big leap is the integration of bionic technology.

Bionic prosthetics, which use sensors and advanced robotics to mimic natural movement, were once considered futuristic and inaccessible due to their high cost.

However, 3D printing is making bionic limbs more affordable, customizable, and widely available to those who need them.

Making Advanced Prosthetics More Affordable

Traditional bionic limbs can cost tens of thousands of dollars, making them out of reach for many individuals. The complexity of manufacturing, the use of expensive materials, and the need for specialized engineering all contribute to these high costs.

3D printing is changing this by reducing production costs significantly. Instead of relying on expensive metal components and intricate manufacturing processes, engineers can now design bionic limbs using strong, lightweight 3D-printed materials.

This not only makes the devices more affordable but also allows for quick adjustments and repairs when needed.

Custom Fit and Personalized Functionality

One of the biggest challenges of bionic prosthetics has always been achieving a perfect fit. Every person’s body is different, and a prosthetic limb must be designed to match their unique shape and movement patterns.

Traditional bionic limbs often require extensive adjustments, adding to the time and cost of production.

With 3D scanning and printing, bionic limbs can now be tailored precisely to the user. By capturing the exact shape of the residual limb and adjusting the prosthetic for optimal movement, users can experience greater comfort and functionality.

Additionally, 3D-printed bionic limbs can be modified with different grip strengths, hand shapes, or movement styles depending on the individual’s lifestyle.

Brain-Controlled and AI-Enhanced Prosthetics

The next step in 3D-printed bionics is the integration of smart technology. Some modern prosthetic limbs are now equipped with sensors that detect muscle signals, allowing users to control movement naturally.

With the help of artificial intelligence (AI), these limbs can even learn and adapt to the user’s unique motion patterns, making movements smoother and more intuitive over time.

3D printing makes it easier to integrate these advanced technologies into prosthetic designs.

For example, researchers are experimenting with embedding flexible sensors directly into 3D-printed prosthetic hands, allowing users to feel pressure, temperature, and texture through artificial touch.

This level of innovation was once only possible with highly expensive, custom-built prosthetics, but 3D printing is making it more accessible to a wider audience.

Expanding Access to Bionic Prosthetics Worldwide

One of the most exciting aspects of 3D-printed bionic limbs is their potential to reach underserved communities.

Many individuals in developing countries lack access to advanced prosthetic technology due to high costs and limited medical infrastructure.

With portable 3D printing units and digital designs that can be shared online, bionic prosthetics can now be created in remote areas at a fraction of the traditional cost.

Organizations and researchers are already using 3D printing to bring affordable bionic limbs to individuals in need, giving them access to technology that was once considered out of reach.

As the field continues to grow, we may soon see a future where advanced, AI-driven prosthetics are available to anyone, regardless of their financial situation.

3D Printing in Assistive Devices for Non-Limb Disabilities

While much of the focus on 3D-printed assistive devices has been on prosthetics, the technology is also transforming the way people with non-limb disabilities access support.

From customized mobility aids to communication tools and adaptive daily-use devices, 3D printing is opening doors for individuals with a wide range of disabilities.

Custom Wheelchair Modifications and Mobility Aids

Standard wheelchairs and mobility aids are often built with a one-size-fits-all approach, which does not always meet the specific needs of each individual.

Many wheelchair users require customized seating arrangements, unique handle grips, or specialized attachments that make daily tasks easier. Traditionally, these modifications have been expensive and difficult to obtain.

With 3D printing, personalized wheelchair accessories can be designed and produced quickly.

Items such as customized joystick holders for powered wheelchairs, lightweight tray attachments for improved accessibility, and ergonomic cushions for better posture support can be tailored to fit the exact needs of the user.

Because these modifications can be made on-demand, users no longer have to wait for expensive, factory-produced components.

3D printing has also enabled the development of ultra-lightweight, foldable wheelchairs that can be printed using durable yet flexible materials.

These innovations are particularly valuable in areas where access to mobility devices is limited, allowing individuals with disabilities to maintain independence and mobility.

Assistive Devices for Communication

For individuals with speech or communication disabilities, 3D printing is helping create more affordable and customized communication aids.

Traditional augmentative and alternative communication (AAC) devices—such as speech-generating tablets and eye-tracking systems—can be costly and difficult to customize for individual users.

3D printing is being used to create personalized AAC device mounts, making it easier for users to position their communication tools in a way that best suits their abilities.

Some researchers are also working on 3D-printed Braille displays that provide a more affordable alternative for individuals with visual impairments.

By reducing production costs, these innovations can make communication devices more accessible to people who need them the most.

Adaptive Tools for Everyday Life

Independence in daily life is a major concern for people with disabilities, and 3D printing is providing new ways to create adaptive tools for eating, dressing, and performing household tasks.

Traditional adaptive devices, such as grip-friendly utensils, buttoning aids, and writing supports, can be expensive and often lack customization.

3D printing allows users to design and create tools that fit their specific needs. For example, individuals with limited grip strength can have custom-built eating utensils that match their hand shape and movement ability.

Similarly, adaptive clothing fasteners, zipper pulls, and key turners can be 3D-printed to make everyday tasks more manageable.

The accessibility of 3D-printed adaptive tools means that users can modify their devices as their needs change. Instead of purchasing expensive commercial solutions, they can adjust designs and print new versions as needed, making independent living more achievable.

Conclusion

The rise of 3D-printed assistive devices is transforming accessibility like never before. By making prosthetics, mobility aids, and adaptive tools more affordable, customizable, and widely available, 3D printing is breaking down barriers for people with disabilities. It is not just improving lives—it is redefining what is possible.

While challenges like durability, regulations, and accessibility still exist, rapid advancements in materials, AI-driven customization, and smart technology are pushing 3D-printed assistive devices closer to mainstream adoption. From children who outgrow prosthetics to individuals in remote areas who need mobility aids, 3D printing is offering faster, better solutions where traditional methods fall short.

At Robobionics, we believe that assistive technology should be innovative, accessible, and designed for real-life needs. As 3D printing continues to evolve, we are committed to staying at the forefront of this revolution, helping individuals regain independence and confidence.

The future of assistive devices is here, and it is being built layer by layer. If you are looking for advanced, customized prosthetics, visit our website today and explore how we can help.