For many families, finding the right prosthetic for a child can feel overwhelming. The process often seems long, expensive, and confusing. And when the prosthetic doesn’t fit well or needs constant repairs, it becomes even harder—for both the child and the parents.

But that’s starting to change.

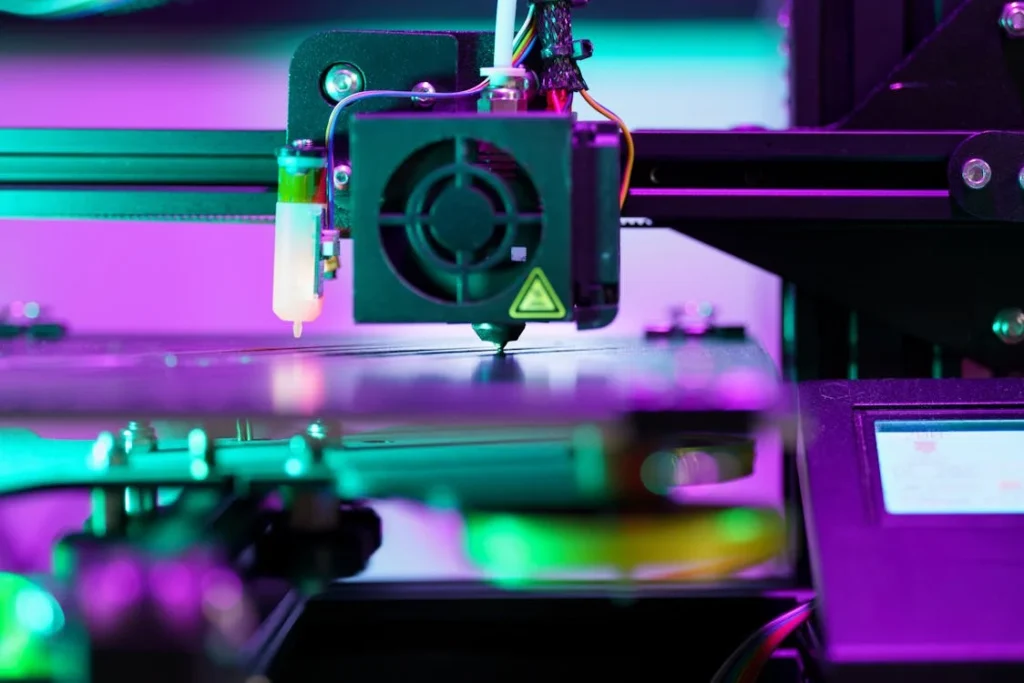

Thanks to 3D printing, we’re seeing a big shift in how prosthetics are made and delivered, especially for children. What once took weeks or months can now happen much faster, and often at a much lower cost. More importantly, prosthetics can now be shaped and sized more accurately to fit each child’s body—and life.

Understanding the Basics: What Makes Pediatric Prosthetics So Challenging?

Children Aren’t Just Small Adults

Designing prosthetics for children is not simply a matter of making smaller versions of adult devices. Children are growing, both physically and mentally.

Their bones get longer, muscles get stronger, and their movement changes almost every few months. A prosthetic that fits today might become uncomfortable or unusable in a short time.

This creates a big challenge for families and clinicians alike: how do you give a child a device that fits well, works well, and grows with them?

Unlike adults, children also learn to move and interact with their environment through trial and error. They run, fall, climb, and explore constantly.

That means a prosthetic for a child needs to be tough, light, and comfortable—not just functional. It also needs to support them in learning basic tasks like holding a pencil, tying shoelaces, or eating with a spoon.

Getting the design wrong doesn’t just limit mobility—it can slow down a child’s overall development.

Traditional methods of making prosthetics involve molds, casting, and manual shaping. These techniques take time and may require several visits to the clinic.

For many families, especially those living far from cities or specialized centers, this can become a costly and stressful experience.

And when the child outgrows the prosthetic in six months or a year, the entire process starts all over again.

The Weight of Cost and Distance

Cost is another major barrier. Custom prosthetics can be expensive, not only because of materials but also due to labor, shipping, and follow-up care.

Imported parts or devices often raise the price further, putting them out of reach for many families. Add in travel expenses and time away from work or school, and the financial burden becomes even heavier.

In rural areas or smaller towns, access is a major issue. There may be no local clinic that offers prosthetic services. Families might have to travel hundreds of kilometers to reach a center that can help.

In the case of traditional prosthetics, this means long wait times, extra travel for fittings, and delays in getting the final device.

This is where 3D printing starts to change the picture. It brings new hope by offering faster production, better personalization, and lower costs—all without sacrificing quality.

How 3D Printing Makes Pediatric Prosthetics More Affordable

Lowering Production Costs

One of the biggest reasons 3D printing is transforming pediatric prosthetics is how much it reduces production costs. Traditional prosthetics often require expensive molds, specialized machines, and skilled technicians who must shape and assemble every part by hand.

These costs add up quickly, especially for growing children who may need a new limb every 6 to 12 months.

With 3D printing, the need for molds or casting materials disappears. The entire limb can be designed using free or low-cost software, and once the digital file is ready, it can be printed using cost-effective materials like thermoplastics or flexible polymers.

These materials are strong enough for daily use but much cheaper than the metals or carbon fiber used in many traditional designs.

For children, who require lightweight and adaptable solutions, this approach works especially well. The lower material cost means families can afford replacements more often, and clinics can offer better pricing without compromising quality.

In some cases, 3D-printed prosthetics cost only a fraction of traditional models, making them accessible to many more families, especially in low-resource areas.

Reducing Time and Labor

Every hour spent on production adds to the final cost of a prosthetic. In traditional settings, shaping, molding, and assembling parts can take days or even weeks.

Each adjustment—whether for size, comfort, or function—might require starting the process again from scratch. This not only takes time but also ties up skilled labor, making it harder for clinics to serve many children at once.

3D printing simplifies much of this process. Once the prosthetic is digitally designed, a technician can start the print and let the machine do the work.

This means fewer working hours are needed for each device, which helps reduce costs further. Clinics can also scale up quickly, serving more children in less time without increasing staff or resources.

The real value here is in how fast children can receive their prosthetic. Faster delivery means they spend less time waiting and more time adjusting, learning, and growing with their new limb.

And when small changes are needed—like resizing the socket or changing a grip—it’s as easy as modifying the digital file and reprinting just that part.

Minimizing Waste

Another hidden cost in traditional prosthetics is material waste. When molds don’t come out right, or when a design needs to be adjusted, leftover materials often cannot be reused.

Over time, this waste adds up, raising costs for both clinics and families.

3D printing is much more efficient. It uses only the material needed to build the object, layer by layer, and most printers produce little to no extra waste.

This efficiency helps lower both cost and environmental impact. Some centers are even exploring the use of recycled plastics, making 3D-printed prosthetics even more sustainable.

For families who are concerned about both affordability and long-term care, this approach offers peace of mind. If a child’s prosthetic breaks or becomes uncomfortable, it doesn’t mean starting over from the beginning.

Just one part can be reprinted, saving time, money, and stress.

What 3D Printing Does Differently

3D printing works by building an object layer by layer from digital designs. Instead of shaping materials by hand, a 3D printer uses software and machines to create exact shapes with incredible accuracy.

This approach brings two major advantages to pediatric prosthetics: speed and customization.

When a child needs a prosthetic, a 3D scanner can capture the size and shape of their limb quickly and without discomfort. These measurements are then used to design a prosthetic that fits perfectly.

Once the design is ready, it can be printed within hours or days—not weeks. And because digital files are easy to store and reuse, future adjustments can happen much faster.

The materials used in 3D-printed prosthetics are strong, lightweight, and safe for children. Designers can even build flexible joints or soft edges into the final product to improve comfort and movement.

And if a part breaks, it can be replaced quickly without needing to redo the entire device.

This is especially helpful for growing children. Instead of waiting months for a new prosthetic, they can get an updated version more quickly and at a lower cost.

Making Pediatric Prosthetics More Accessible Through 3D Printing

Reaching Underserved Communities

In many parts of India and across the world, children living in rural or low-income areas often go without prosthetic care. Specialized clinics tend to be located in large cities, and travel can be expensive and time-consuming.

For some families, the nearest prosthetic center might be hundreds of kilometers away. Even when they can make the trip, follow-up visits, fittings, and repairs create more barriers.

3D printing offers a practical way to bring prosthetic care closer to home. Because the technology relies on digital files and compact machines, it doesn’t require a large manufacturing setup.

Small labs, schools, or even mobile clinics can be equipped with 3D printers and trained technicians. This creates the possibility of producing prosthetics in or near the communities that need them most.

Design files can be shared online or through cloud-based systems. A clinic in one city can collaborate with a rural center by sending a custom design file that can then be printed locally.

This drastically reduces wait times and avoids the need for repeated travel. It also builds local capacity, as community health workers can be trained to assist in scanning, printing, and fitting the devices.

The result is not just faster service—it’s true accessibility. Children who would otherwise go without prosthetics now have a real chance to receive the care they deserve.

Supporting Inclusive Design

Every child is different, not just in size but also in lifestyle, goals, and personality. A prosthetic that works well for one child may not suit another.

3D printing makes it easier to include these differences in the design process. Instead of relying on fixed sizes and models, technicians can adjust each device to match a child’s exact limb shape and activity level.

More importantly, it allows for feedback from the children and families themselves. If a child finds a grip uncomfortable or wants a different style, those changes can be made quickly.

The design process becomes more collaborative, where children feel part of creating something that belongs to them—not just something they have to use.

This sense of ownership encourages better use and faster adaptation. When a child feels that their prosthetic is made just for them, they’re more likely to wear it regularly, explore its full range, and grow confident in their abilities.

This emotional connection can be just as important as the technical performance of the device.

Custom designs can also reflect the child’s interests and personality. Whether it’s a favorite color, a cool shape, or a fun pattern, these small touches make a big difference in how a child sees their prosthetic—not as a limitation, but as something uniquely theirs.

Training the Next Generation of Innovators

One of the most exciting outcomes of 3D printing in prosthetics is the new wave of innovation it brings.

As the technology becomes more affordable and widely taught, more young engineers, designers, and clinicians are learning how to apply it to solve real-world problems.

Universities, nonprofits, and startups across India and globally are working on open-source prosthetic designs and low-cost printing solutions.

These efforts are creating a growing community of people who are passionate about using technology to make healthcare more equal.

In the long run, this growing knowledge base means more local talent, faster solutions, and greater resilience in the system.

If a child’s prosthetic breaks or they need a new fitting, there’s no need to wait for a far-off factory to respond. Skilled people nearby can step in and help.

This kind of progress not only increases access—it empowers communities. It helps shift prosthetic care from something rare and expensive to something normal, local, and sustainable.

The Role of 3D Printing in Future-Proofing Pediatric Prosthetics

Keeping Up With Growth

Children grow fast. What fits today might not fit in six months. This has always been one of the biggest challenges in pediatric prosthetic care.

A limb that becomes too small can cause pain, poor posture, or even injury. But constantly replacing full prosthetic devices is costly and time-consuming.

3D printing helps solve this problem by allowing for quick and affordable adjustments. Since prosthetics are designed digitally, resizing the limb to match a child’s growth is much easier than starting from scratch.

The same design file can be updated, resized, and reprinted without the need to go through a lengthy molding process. In some cases, only a specific part—like the socket or grip—needs replacing, not the entire limb.

This flexibility gives parents and clinics a way to plan ahead. Instead of worrying about when the prosthetic will need to be replaced, they can focus on how to help the child grow into their abilities.

When the process of updating a device becomes simpler, the entire experience becomes more supportive and less stressful.

Improving Speed Without Cutting Corners

In traditional prosthetics, there’s always a trade-off between speed and quality. Rushing a device can lead to poor fit, reduced comfort, or weak materials.

But waiting too long leaves a child without the tools they need to explore, learn, and stay active.

3D printing narrows this gap. It allows prosthetists to move faster without cutting corners. A device can be scanned, designed, and produced in days, not weeks.

But because the design is precise and the printing process is controlled, the final prosthetic can still meet high standards of fit and function.

This is especially helpful during early rehabilitation, when a child is still adjusting to the idea of using a prosthetic. Early success builds confidence.

If the first device is delayed or feels uncomfortable, it can affect how the child sees their ability to adapt. But if the prosthetic is ready quickly and fits well, the child is more likely to keep practicing and using it.

As new tools and materials enter the 3D printing space, the speed will continue to improve. More durable, skin-friendly filaments are being developed.

New printers are offering finer resolution and stronger prints. All of this makes it possible to deliver high-quality prosthetics faster than ever before.

Creating Opportunities for Lifelong Impact

The benefits of 3D-printed pediatric prosthetics go far beyond the device itself. When a child has access to a well-fitting, reliable prosthetic early on, it sets the foundation for lifelong health, learning, and independence.

Children with prosthetics learn problem-solving skills early. They grow up knowing how to adapt, how to stay active, and how to participate in daily life fully.

They also gain confidence, which shapes how they see themselves and how others see them.

As 3D printing becomes more common in healthcare, we are likely to see even more progress. Integrated sensors, touch feedback, and smarter limb control systems are already being tested in labs.

And because 3D printing makes it easier to test new ideas quickly, these innovations could become more available to children much sooner than before.

How Personalization Through 3D Printing Supports Emotional Growth in Children

More Than Just a Medical Device

For a child, a prosthetic isn’t just something they wear—it becomes a part of their body image. How it looks, how it feels, and how it moves all play a role in shaping how the child sees themselves.

Traditional prosthetics often look generic and medical. They’re built more for function than for feeling. That can send a quiet message to a child that their limb difference is something to hide or “fix.”

3D printing brings a completely different approach. It offers the ability to design prosthetics that reflect the child’s personality, interests, and choices.

This might mean choosing their favorite color, adding textures they like, or shaping the hand in a way that feels fun or even futuristic.

Some children want a robotic look; others want something soft and friendly. And because 3D-printed limbs are designed digitally, these choices can be easily included.

These small customizations may seem minor from a technical point of view—but emotionally, they carry weight. A prosthetic that looks exciting or expressive becomes something the child feels proud of.

It can shift the experience from “I have to wear this” to “This is mine. This is me.” That sense of ownership can make a huge difference in daily life.

Boosting Confidence Through Representation

Feeling seen is a powerful thing, especially for a child. Many children with limb differences feel isolated, especially if they don’t see others like themselves in school, on TV, or even in books.

A prosthetic that feels unique and chosen—rather than imposed—can help reduce that sense of separation.

When children are included in the design process, they become active participants in their care. They learn to make decisions, express preferences, and talk openly about what they want.

That builds emotional strength, as well as the kind of self-advocacy skills they’ll carry into adolescence and adulthood.

With 3D printing, children can even take part in watching their prosthetic being printed. Seeing it built layer by layer helps them understand how it works and reduces fear or anxiety about using it.

It turns the experience into something creative and empowering.

Making Social Interaction Easier

Children are sensitive to how others respond to their appearance. An unfamiliar-looking prosthetic can attract stares or awkward questions, especially in school or public places.

If the prosthetic looks stiff, clunky, or out of place, the child may feel the need to explain themselves—or worse, withdraw.

Custom-designed prosthetics, especially those made with 3D printing, can flip that script. When the limb looks like a cool gadget, a superhero arm, or something fun and artistic, other kids become curious in a positive way.

They may ask questions out of admiration rather than discomfort. This helps the child feel more included, and helps others see the prosthetic as something amazing—not strange.

The emotional benefit here is long-term. When children grow up feeling proud of their prosthetic and accepted by their peers, they develop resilience.

They’re more likely to stay socially active, explore new spaces, and speak up for themselves—all of which are essential for healthy emotional growth.

Iterative Design: How 3D Printing Enables Rapid Feedback and Continuous Improvement

Designing in Real Time With the Child’s Needs in Mind

Traditional prosthetic development can be a slow process. After taking measurements, a device is often made off-site, and the child may wait weeks before seeing or trying it. Once they do, if something doesn’t feel right, they may need to wait again for adjustments—sometimes more than once.

This lag time can be discouraging and can even lead to a child giving up on using the prosthetic altogether.

3D printing changes that dynamic completely. Because the process is fast and flexible, designers and prosthetists can take a more interactive, real-time approach.

If a child tries a prosthetic and says, “This part feels too tight,” or “I can’t reach far enough,” the design can be tweaked right away.

That change is made on the computer, reprinted locally, and ready for another try—often within days, sometimes even hours.

This loop of trial, feedback, and improvement makes the prosthetic not just better—it makes it truly personal. It creates a sense of collaboration between the prosthetist, the child, and the family, where everyone is working together to create the best fit.

For children, especially those new to prosthetics, this kind of support can mean the difference between frustration and progress.

Better Outcomes Through Real-World Testing

Many prosthetic challenges don’t show up in the clinic—they appear when the child goes home. For example, a socket might feel fine during a short fitting but begin to cause discomfort after a few hours of use.

Or a hand grip might work well on smooth surfaces but struggle to hold school supplies or sports gear.

Because 3D printing allows for fast iteration, these real-world discoveries can be addressed quickly. Families no longer have to “settle” for what they’re given.

If something doesn’t work, it can be changed. Over time, this leads to better comfort, better performance, and higher satisfaction—especially in pediatric users, who are still learning to communicate what they feel.

In traditional prosthetic manufacturing, this kind of responsive change is often difficult. A single redesign might require a new mold, which means more cost, more time, and more effort.

This discourages experimentation and puts pressure on “getting it right the first time.”

With 3D printing, experimentation becomes part of the process. Designers can test new materials, joint shapes, or socket contours without committing to full production.

And when a child’s needs change—as they grow, gain strength, or learn new skills—those needs can be reflected in the next iteration almost immediately.

Supporting Inclusive Innovation

Another powerful aspect of fast iteration is how it opens up innovation to more people. In the past, prosthetic design was mostly in the hands of specialists in large hospitals or research centers.

Now, with 3D printing, smaller clinics, students, or local innovators can create, test, and improve new designs based on their unique community needs.

This shift is especially important in a diverse country like India, where local customs, climates, and lifestyles vary so widely.

A prosthetic that works well in a metro city may not be suited for a child living in a rural area who walks long distances or helps with family work.

The ability to design and test different solutions locally—and refine them quickly—is a major step toward equity in healthcare.

By encouraging ongoing experimentation and feedback, 3D printing not only makes prosthetics more functional—it makes them more human. It allows the child’s voice to be part of the design, every step of the way.

Conclusion

3D printing is not just a new way to build prosthetics—it’s a new way to think about care. For children, whose needs change quickly and whose futures are still unfolding, this technology offers more than just a better fit. It offers faster access, lower costs, and the chance to shape something that feels truly their own.

By allowing for quicker design changes, local production, and greater personalization, 3D printing removes many of the barriers that once made pediatric prosthetic care slow, expensive, and out of reach for many families. It turns a complex process into one that’s more flexible, more responsive, and more empowering—for both children and their caregivers.

As the technology grows, so does its potential to make prosthetic care more inclusive, more creative, and more connected to real life. For many children, this isn’t just a tool—it’s a beginning.