Advancements in prosthetic technology have changed the way athletes with limb differences train, compete, and perform. Among these breakthroughs, 3D printing has emerged as a game-changer, making it easier to create custom sports prosthetics that are lightweight, strong, and tailored to individual needs.

Traditional prosthetics often take weeks to manufacture and require multiple fittings to ensure a proper fit. With 3D printing, the process is faster, more precise, and cost-effective. Athletes can now get prosthetics designed specifically for their sport, whether it’s running, cycling, swimming, or weightlifting. These customized designs enhance performance, improve comfort, and allow athletes to push their limits without restrictions.

How 3D Printing is Changing the Design Process of Sports Prosthetics

The traditional way of making prosthetics involves a time-consuming and expensive process. It starts with a mold of the residual limb, followed by multiple fittings and adjustments to ensure comfort and function.

This method, while effective, is not always efficient, especially for athletes who need high-performance prosthetics that match their specific sport.

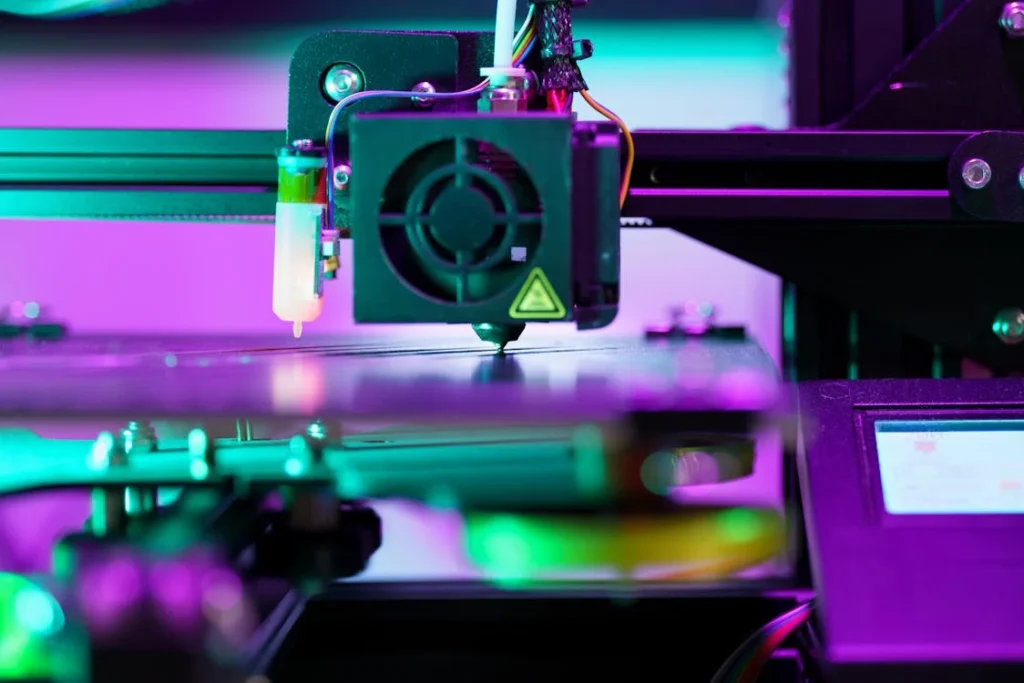

3D printing has transformed this process by making it faster, more accurate, and fully customizable. The journey begins with a digital scan of the athlete’s limb. This scan creates a precise 3D model, eliminating the need for physical molds.

Prosthetists and engineers then design the prosthetic using specialized software, adjusting its shape, weight distribution, and flexibility to meet the athlete’s needs.

Once the design is finalized, a 3D printer builds the prosthetic layer by layer using advanced materials like carbon fiber composites, titanium, and high-strength plastics.

This method allows for incredibly detailed and precise structures that would be difficult to achieve using traditional manufacturing techniques.

Since 3D printing does not require expensive molds or extensive labor, the cost of production is significantly lower, making custom sports prosthetics more accessible to a wider range of athletes.

The Benefits of 3D-Printed Prosthetics for Athletes

One of the biggest advantages of 3D-printed prosthetics is their ability to be fully customized. Every athlete has unique physical requirements based on their limb structure, sport, and personal preferences.

With 3D printing, adjustments can be made quickly, ensuring a perfect fit and maximum comfort. This is especially important for high-impact sports, where even small discomforts can lead to pain, irritation, or performance issues.

Weight is another crucial factor. Traditional prosthetics, especially those made for sports, can be heavy due to the materials used in their construction.

3D printing allows for the creation of hollow or lattice structures that reduce weight without compromising strength. A lighter prosthetic means less energy is needed to move, improving endurance and agility.

Durability is equally important. Sports prosthetics must withstand significant stress, whether it’s the impact of running, the force of lifting weights, or the resistance of swimming.

Materials used in 3D printing, such as reinforced polymers and carbon fiber composites, offer exceptional strength and resilience. Athletes can train and compete with confidence, knowing their prosthetic will hold up under pressure.

Another major advantage of 3D printing is the ability to quickly replace or upgrade prosthetic components.

If an athlete needs a different socket fit, a more aerodynamic running blade, or a stronger grip for a cycling prosthetic, adjustments can be made in a matter of days rather than weeks.

This rapid production cycle ensures that athletes always have the best possible equipment for their performance.

How 3D Printing Enhances Performance Across Different Sports

Every sport places unique demands on the body, and prosthetic requirements vary based on the type of movement, force, and endurance needed.

3D printing allows prosthetics to be designed with sport-specific adaptations, ensuring athletes can perform at their highest level without restrictions.

Running and Sprinting

For runners, speed, efficiency, and shock absorption are crucial. 3D-printed running blades are designed to return as much energy as possible with every stride, mimicking the elasticity of a natural leg.

Unlike traditional carbon fiber blades that require complex molding processes, 3D printing allows for intricate, hollow lattice designs that reduce weight while maintaining strength.

These custom designs can be fine-tuned for an athlete’s specific running style, helping them achieve better control, balance, and endurance.

Another major advantage is the ability to experiment with different shapes and stiffness levels. Traditional running prosthetics are often mass-produced with limited customization options.

With 3D printing, prosthetists can test multiple designs, making small changes to optimize performance without the high costs of traditional manufacturing.

This means that runners can have blades tailored specifically to their body mechanics and running conditions, giving them an edge in competition.

Cycling

Cyclists rely heavily on power transfer, aerodynamics, and stability. A 3D-printed cycling prosthetic is designed to fit securely into the pedal system, ensuring maximum energy efficiency with every rotation.

Since cycling involves repetitive motion, the prosthetic must be lightweight and properly aligned to prevent strain on the knee and hip.

One of the breakthroughs in 3D-printed cycling prosthetics is the ability to create customized socket designs that distribute pressure evenly across the residual limb.

This reduces discomfort and allows cyclists to maintain performance over long distances. Some prosthetics even include built-in shock absorbers to handle vibrations from rough terrain, improving comfort and reducing fatigue.

Swimming

Water resistance creates a unique challenge for amputee swimmers. Unlike land-based sports, where prosthetics focus on energy return and stability, swimming prosthetics need to minimize drag while maximizing propulsion.

3D printing allows for the creation of hydrodynamic limb designs that reduce water resistance and enhance movement efficiency.

Some swimmers use 3D-printed fins attached to their prosthetic limbs, helping them generate more force with each kick. These fins are designed with precision, adjusting the curvature and flexibility to match the swimmer’s stroke style.

Additionally, waterproof, corrosion-resistant materials ensure that the prosthetic remains durable even after prolonged exposure to chlorine or saltwater.

Strength Training and Weightlifting

Athletes involved in strength training and weightlifting need prosthetics that can handle heavy loads without sacrificing flexibility or comfort. 3D-printed weightlifting prosthetics are designed with reinforced structures that provide superior grip and stability.

Some designs feature mechanical locking mechanisms that allow for better control when lifting barbells, ensuring a secure hold without excessive strain on the residual limb.

Additionally, the customization of 3D-printed sockets ensures that weight is distributed evenly across the limb, reducing pressure points and preventing injuries.

Since each athlete has different strength levels and lifting techniques, prosthetics can be fine-tuned to match their specific needs, allowing for safer and more efficient performance.

The Accessibility and Affordability of 3D-Printed Sports Prosthetics

One of the most significant benefits of 3D printing in prosthetics is its potential to make high-performance sports limbs more affordable and accessible.

Traditional prosthetics are expensive due to the labor-intensive manufacturing process, costly materials, and the need for multiple adjustments.

For athletes, this often means long wait times and financial barriers that limit their ability to obtain a prosthetic suited for their sport.

With 3D printing, costs are significantly reduced. Since digital scanning and computer-aided design (CAD) replace manual molding, the need for expensive casting materials and extensive labor is minimized.

Once a prosthetic design is finalized, it can be printed in a fraction of the time it would take to manufacture a traditional prosthetic.

This not only lowers costs but also makes prosthetics more readily available to athletes in developing countries or those with limited access to advanced medical facilities.

Another major advantage of 3D printing is its ability to create modular prosthetics. Instead of replacing an entire prosthetic when an athlete outgrows it or requires adjustments, individual components can be reprinted and replaced as needed.

This is especially beneficial for young athletes, whose bodies change as they grow. With traditional prosthetics, frequent replacements can be costly, but with 3D printing, modifications can be made at a much lower price.

Customization also plays a big role in accessibility. Unlike mass-produced prosthetics that may not fit every individual perfectly, 3D-printed prosthetics can be tailored to an athlete’s exact limb shape, reducing discomfort and improving overall function.

This personalized approach ensures that more amputees can participate in sports at all levels, from recreational to elite competition.

Reducing Waste and Supporting Sustainability

Beyond cost and accessibility, 3D printing also offers environmental benefits by reducing material waste. Traditional prosthetic manufacturing involves cutting, shaping, and discarding excess materials, leading to significant waste.

With 3D printing, prosthetics are created layer by layer using only the material necessary for the design, minimizing excess.

Additionally, many 3D-printed prosthetics are made from recyclable or biodegradable materials. Some research efforts are focused on developing prosthetic components using plant-based polymers or recycled plastics, making the industry more sustainable.

As environmental consciousness grows, the shift toward 3D-printed prosthetics could help reduce the carbon footprint associated with traditional production methods.

The Future of 3D Printing in Sports Prosthetics

The role of 3D printing in sports prosthetics is still evolving, and the future holds even more exciting possibilities. As technology continues to advance, prosthetic limbs will become lighter, stronger, and more adaptable to different sports.

Innovations in materials, artificial intelligence, and biomechanics will further improve how athletes use prosthetics, making them feel more like natural extensions of the body.

Advancements in Smart Prosthetics

One of the most promising developments in 3D-printed prosthetics is the integration of smart technology. Researchers are working on prosthetic limbs that can adapt to an athlete’s movements in real time.

These intelligent prosthetics use embedded sensors and AI-driven systems to analyze how a person runs, jumps, or cycles. Based on this data, the prosthetic can adjust stiffness, flexibility, and energy return, optimizing performance for different conditions.

For example, a runner using a 3D-printed blade could benefit from a prosthetic that automatically changes its response depending on terrain.

On a flat road, it could provide maximum energy return for speed, while on an uphill section, it could adjust stiffness to improve efficiency.

These adaptive systems could help athletes conserve energy, reduce strain on their residual limbs, and fine-tune their movements without manual adjustments.

Personalized Biomechanics and Custom Fit

Customization is one of the biggest strengths of 3D printing, and the future will see even greater personalization of prosthetics. Instead of relying on standard prosthetic sizes and shapes, athletes will have limbs that are designed based on their specific biomechanics.

Using motion capture technology, pressure sensors, and 3D limb scanning, prosthetists will be able to create prosthetics that perfectly match an individual’s running style, gait pattern, and muscle strength.

This level of personalization will go beyond just comfort and fit. It will allow athletes to maximize their performance by ensuring that their prosthetic works in harmony with their body.

Runners will have blades designed to match their foot strike pattern, swimmers will have prosthetics shaped to minimize water resistance, and weightlifters will have limbs reinforced in areas where they apply the most force.

Another exciting possibility is the use of shape-memory materials that adjust their structure based on an athlete’s activity. A prosthetic limb designed for multiple sports could change its stiffness when switching from sprinting to jogging, or from running to cycling.

This would eliminate the need for multiple prosthetic attachments, making it easier for multi-sport athletes to train and compete.

The Role of 3D Printing in Paralympic and Competitive Sports

As 3D printing becomes more advanced, its impact on professional and Paralympic sports will grow. Today, many elite athletes already use custom 3D-printed prosthetics, but in the future, these technologies will become even more specialized.

The ability to rapidly prototype and test new designs will allow athletes to continually refine their equipment, gaining a competitive edge.

Governing bodies in adaptive sports are also recognizing the benefits of 3D-printed prosthetics. In the past, rules regarding prosthetic technology were restrictive, but as 3D printing makes prosthetics more accessible, the conversation is shifting toward inclusivity.

More athletes will have access to high-performance prosthetics, leveling the playing field and ensuring that competition is based on skill rather than financial ability to afford expensive equipment.

Beyond competition, the rise of 3D printing in sports prosthetics will inspire a new generation of athletes with disabilities. Young amputees will see that prosthetics are not just medical devices but tools that can help them reach their athletic goals.

With lower costs, improved accessibility, and increased awareness, more people will be encouraged to participate in sports, leading to a future where limb difference is no longer a barrier to competition or personal achievement.

How 3D Printing is Empowering Athletes with Disabilities

Beyond the technical advancements and performance benefits, 3D printing is playing a critical role in changing perceptions around disability in sports.

For many years, access to high-quality prosthetics was limited to elite athletes or those who could afford expensive, custom-made limbs.

With the rise of 3D printing, that barrier is being broken down, allowing more amputees to pursue their passion for sports without financial or logistical obstacles.

Making Sports More Inclusive

One of the biggest challenges for athletes with limb differences has been the high cost of prosthetic limbs. Traditional sports prosthetics require extensive customization, expensive materials, and multiple fittings, making them unaffordable for many people.

3D printing has dramatically reduced these costs by streamlining the manufacturing process. Instead of waiting months for a prosthetic to be built and adjusted, athletes can now receive a fully customized limb in a matter of weeks at a fraction of the price.

This affordability has led to a rise in community sports programs for amputees. More children and young athletes are gaining access to prosthetics that allow them to participate in recreational and competitive sports.

Schools, universities, and adaptive sports organizations are embracing 3D printing as a way to provide affordable prosthetics to students, ensuring that no child is left out of physical activities due to limb loss.

In developing countries, where access to prosthetics is often limited, 3D printing is revolutionizing the way sports prosthetics are distributed.

Nonprofit organizations and medical institutions are using open-source designs to print custom prosthetics for individuals who previously had no access to them.

This has created a new wave of amputee athletes who now have the opportunity to train and compete, proving that disability should never be a barrier to sports.

Encouraging Innovation and Personal Expression

One of the most exciting aspects of 3D-printed prosthetics is the ability to personalize them not just for function, but also for aesthetics.

Athletes no longer have to settle for generic-looking limbs—3D printing allows for creative designs, vibrant colors, and even prosthetics inspired by futuristic or artistic concepts.

Some athletes choose to customize their prosthetics with designs that reflect their personality, cultural heritage, or favorite sports teams.

This level of personalization fosters a sense of pride and empowerment, helping amputees embrace their prosthetic limbs as an extension of their identity rather than just a medical device.

Additionally, 3D printing has sparked a culture of innovation within the prosthetics industry. Engineers, designers, and athletes themselves are collaborating to push the boundaries of what sports prosthetics can achieve.

Open-source prosthetic designs are being shared worldwide, allowing experts and hobbyists alike to contribute to the advancement of prosthetic technology.

This has created a global movement focused on making sports more accessible and ensuring that amputees have the tools they need to succeed.

Changing the Narrative Around Disability in Sports

For many years, adaptive sports were viewed as separate from mainstream athletics. However, with the growing use of 3D printing in sports prosthetics, that divide is shrinking.

Athletes with prosthetic limbs are proving that they can compete at the highest levels, challenging outdated perceptions of disability and redefining what is possible.

As prosthetic technology continues to improve, the conversation is shifting from limitation to performance. More people are beginning to see that an athlete with a well-designed prosthetic is not “overcoming” a disability, but rather excelling with the right tools.

This shift in perspective is leading to greater support for adaptive sports, increased sponsorship opportunities, and more visibility for amputee athletes in global competitions.

The impact of 3D printing in sports prosthetics goes beyond the individual athlete. It is helping to create a world where inclusion in sports is not an exception, but the norm.

As technology becomes more widely available, the number of amputee athletes will continue to grow, inspiring future generations and proving that innovation, determination, and passion can break down any barrier.

The Role of Research and Development in 3D-Printed Sports Prosthetics

The success of 3D-printed prosthetics in sports is not just the result of manufacturing advancements; it is also driven by continuous research and development.

Scientists, engineers, prosthetists, and athletes work together to refine prosthetic designs, explore new materials, and improve the overall functionality of sports prosthetics.

As this research progresses, the performance gap between natural limbs and prosthetics continues to shrink.

Experimenting with Advanced Materials

One of the most exciting areas of research in 3D-printed prosthetics is the development of new materials that enhance strength, flexibility, and durability.

Traditional prosthetics often rely on carbon fiber, titanium, or aluminum, but 3D printing allows for the creation of composite materials that offer superior performance while remaining lightweight.

Researchers are now experimenting with high-performance polymers and graphene-infused filaments that offer both strength and elasticity.

These materials improve energy return, which is critical for athletes who rely on their prosthetics for explosive movements like sprinting and jumping.

Some experimental designs even incorporate bio-inspired structures, mimicking the shock-absorbing abilities found in nature to create more efficient running blades and impact-resistant prosthetic sockets.

The Influence of Biomechanics in Prosthetic Design

Understanding human biomechanics is essential for designing prosthetics that feel natural and maximize an athlete’s performance.

Motion analysis technology, including 3D gait analysis and pressure mapping, allows researchers to study how amputee athletes move with prosthetics. This data is used to optimize the shape, weight distribution, and alignment of 3D-printed prosthetics.

By studying how force is applied during different sports, engineers can create prosthetic limbs that better distribute impact and reduce strain on the residual limb.

For example, in long-distance running, excessive stress on the hip and lower back can lead to injuries over time. New 3D-printed prosthetics are being designed with shock-absorbing layers that help minimize this stress, improving endurance and reducing the risk of injury.

Additionally, research into asymmetric gait patterns helps athletes train more effectively. Many amputees naturally compensate for their prosthetic limb by altering their movement, which can lead to muscle imbalances.

Advanced prosthetic designs, informed by biomechanical research, are helping correct these issues by promoting a more symmetrical running or walking pattern.

AI and Machine Learning in Prosthetic Optimization

Artificial intelligence (AI) and machine learning are playing an increasingly important role in the development of 3D-printed prosthetics. By analyzing movement data from athletes, AI algorithms can predict how a prosthetic limb will perform under different conditions.

This information allows engineers to make real-time adjustments to the design before printing, ensuring that each prosthetic is tailored for maximum efficiency.

Some experimental prosthetics are even being developed with embedded sensors that provide real-time feedback to athletes. These sensors track factors such as stride length, impact force, and energy efficiency, helping runners and cyclists fine-tune their technique.

In the future, AI-driven prosthetics could adapt dynamically to different terrains, allowing athletes to switch between surfaces like pavement, grass, and sand without losing efficiency.

Collaboration Between Athletes and Engineers

One of the most important aspects of research and development in 3D-printed sports prosthetics is the close collaboration between athletes and engineers.

Unlike traditional prosthetics, which are designed primarily by medical professionals, modern sports prosthetics are created with direct input from the people who use them every day.

Elite amputee athletes frequently test prototypes, providing feedback on comfort, performance, and usability. This hands-on approach ensures that every improvement is practical and beneficial for real-world competition.

Many of the innovations seen in today’s running blades, cycling prosthetics, and adaptive swimming limbs are the result of continuous feedback loops between athletes and designers.

The impact of this collaboration extends beyond professional sports. Everyday prosthetic users benefit from the same advancements, as improvements in sports prosthetics often translate into better mobility and functionality for non-athletic amputees.

This is helping create a new generation of prosthetic limbs that are not only performance-driven but also adaptable to daily life.

The Future of 3D-Printed Prosthetics in the Sports Industry

With ongoing research, the future of 3D-printed sports prosthetics looks incredibly promising. As technology advances, prosthetics will become even more integrated with the athlete’s body, offering greater responsiveness and control.

The combination of lightweight materials, AI-driven adaptability, and personalized biomechanical optimization will push the boundaries of human performance.

The ultimate goal is to create prosthetics that feel so natural that the distinction between biological limbs and artificial limbs becomes almost invisible.

With continued innovation, the dream of fully integrating prosthetics into mainstream sports—without limitations or restrictions—is becoming a reality.

Conclusion

3D printing has revolutionized the world of sports prosthetics, making them more accessible, customizable, and high-performing than ever before. By streamlining the manufacturing process, reducing costs, and enabling rapid innovation, this technology has empowered athletes with limb differences to compete at the highest levels.

Advancements in materials, biomechanics, and artificial intelligence are pushing the boundaries of what prosthetics can achieve. From lightweight running blades with enhanced energy return to adaptive cycling and swimming prosthetics, 3D printing is helping athletes fine-tune their performance with unparalleled precision.

Beyond competition, this technology is making sports more inclusive, allowing more individuals—regardless of financial or geographical barriers—to access prosthetics tailored to their needs. The collaboration between engineers, prosthetists, and athletes is driving continuous improvements, ensuring that future prosthetics will be even more efficient, comfortable, and personalized.

As research and development progress, the line between natural limbs and prosthetic limbs will continue to blur. With innovation at the forefront, 3D-printed prosthetics are not just transforming sports—they are redefining what is possible for amputee athletes worldwide. The future of sports prosthetics is here, and it is limitless.