Bionic arms, once a feature of futuristic science fiction, are now a reality. These advanced prosthetics have the potential to restore independence, functionality, and confidence to individuals with limb loss. However, the high cost of these devices has made them inaccessible to many who could benefit from them the most. Bridging the gap between affordability and cutting-edge technology is not just a technical challenge—it’s a moral imperative.

This article explores how affordable bionic arms are reshaping the prosthetics landscape, the innovative technologies that make them possible, and strategies for reducing costs without compromising quality. At Robobionics, we believe that cost should never be a barrier to regaining freedom. Through intelligent design and a user-first approach, we’re making advanced prosthetics more accessible for everyone.

The Importance of Accessibility in Bionic Arms

The human need for functionality and dignity should not depend on income or geographic location. Yet, for many, advanced prosthetic options remain prohibitively expensive.

Traditional bionic arms, with their intricate mechanical systems and cutting-edge features, often come with a price tag that places them out of reach for the average person.

Understanding Accessibility Beyond Affordability

While affordability is a critical component of accessibility, it’s only the starting point. Accessibility involves removing physical, logistical, and technological barriers that prevent users from fully benefiting from a bionic arm.

For instance, a prosthetic may be affordable but fail to be accessible if it requires advanced technical knowledge to operate.

Similarly, a cutting-edge design is ineffective if users in rural areas cannot access fitting centers or repair services. Businesses need to adopt a holistic view of accessibility to create meaningful, lasting solutions.

Localized Solutions for Diverse Communities

Accessibility often means tailoring solutions to meet the unique needs of different communities. In some regions, users may require durable and low-maintenance prosthetics due to limited access to repair facilities. In others, cultural or aesthetic preferences may play a significant role in user acceptance.

Businesses can benefit from working with local experts, clinics, and community leaders to understand these nuanced needs.

Collaborative design workshops, where users actively participate in shaping the product, can result in bionic arms that are not only functional but also culturally and socially resonant.

Empowering Users Through Training and Support

A truly accessible bionic arm doesn’t end at the fitting stage—it begins there. Many users require training to understand and master their prosthetic device. Without proper guidance, even the most advanced prosthetic can feel daunting.

Businesses can invest in creating user-friendly training materials, from video tutorials to interactive apps that walk users through the basics of their bionic arm. Partnering with clinics to offer hands-on workshops can also make a significant difference in user adaptability.

Ongoing support is equally vital. Offering accessible customer service channels, such as hotlines or online chat support, ensures that users can address their concerns without delays. This not only enhances user experience but also builds trust and brand loyalty.

Strategic Partnerships to Expand Accessibility

Accessibility challenges are rarely solved in isolation. Businesses that collaborate with governments, NGOs, and healthcare providers can amplify their impact. Public-private partnerships can help reduce costs through subsidies, grants, or insurance coverage.

For example, businesses can work with government programs to ensure that affordable bionic arms are included in national healthcare schemes.

Similarly, teaming up with non-profits to provide prosthetics to underserved communities can expand access while strengthening corporate social responsibility efforts.

Integrating Accessibility into Design Philosophy

Accessibility should be embedded into every stage of the design process, from ideation to manufacturing. This involves prioritizing simplicity, ensuring that the bionic arm is intuitive to use and maintain.

Designers can focus on creating devices that are lightweight, easy to clean, and require minimal adjustments. Components should be durable enough to withstand diverse environmental conditions, from humid tropics to arid climates.

Additionally, modular designs offer a strategic advantage. By allowing users to replace or upgrade individual parts, businesses can cater to a wider range of users while reducing long-term costs.

Accessibility as a Market Opportunity

By addressing accessibility, businesses open themselves to untapped markets. The demand for affordable and functional bionic arms extends beyond individual users—it includes hospitals, clinics, and non-profit organizations looking for scalable solutions.

Creating accessible products also generates goodwill and enhances brand reputation. Users who feel empowered by their prosthetics are more likely to share positive experiences, generating organic word-of-mouth promotion.

For businesses, this translates into a loyal customer base and a stronger competitive position.

Challenges in Making Bionic Arms Affordable

Reducing the cost of bionic arms is not without challenges. The complexity of the technology, the specialized materials required, and the precision engineering involved all contribute to high production costs.

Additionally, research and development (R&D) efforts to continually improve functionality add another layer of expense.

Manufacturers face the challenge of striking a delicate balance: maintaining high performance and durability while cutting production and operational costs. Overcoming this requires a multi-faceted approach that involves innovation, partnerships, and economies of scale.

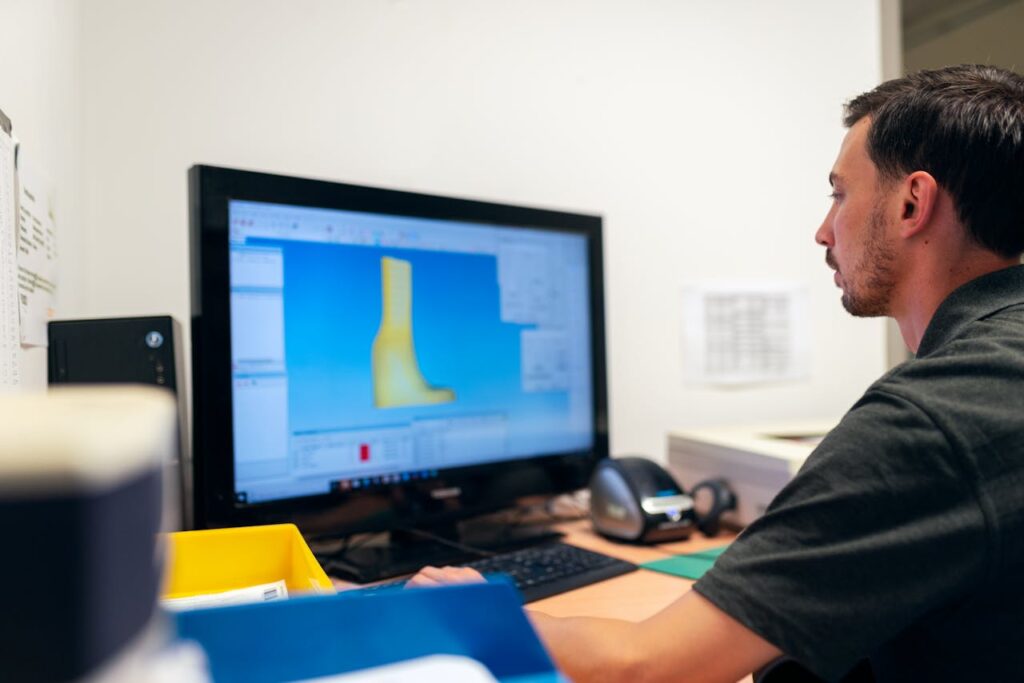

The Role of 3D Printing in Cost Reduction

One of the most transformative technologies in making bionic arms affordable is 3D printing. This technology has revolutionized the manufacturing process by reducing the time and cost involved in creating prosthetic components.

How 3D Printing Works for Prosthetics

3D printing, also known as additive manufacturing, builds objects layer by layer using digital models. For prosthetics, this means highly customizable designs that perfectly fit an individual’s unique anatomy. By using 3D-printed parts, manufacturers can create lightweight and functional bionic arms at a fraction of the cost of traditional methods.

Advantages of 3D Printing in Bionics

- Customization: Each arm can be tailored to the specific measurements and needs of the user without significantly increasing production costs.

- Material Efficiency: Additive manufacturing minimizes waste, using only the necessary materials for each component.

- Rapid Prototyping: New designs can be tested and iterated quickly, speeding up innovation cycles and reducing R&D costs.

By leveraging 3D printing, companies like Robobionics can create high-quality bionic arms that meet the needs of users while keeping prices accessible.

Streamlined Design: Simplicity Without Sacrificing Functionality

Another way to lower the cost of bionic arms is through streamlined design. Instead of focusing on complex features that may only benefit a small subset of users, manufacturers can prioritize core functionalities that meet the majority of needs.

For example, a bionic arm with fewer moving parts can still offer precise grip, adjustable tension, and basic wrist rotation. By focusing on essential movements and functions, manufacturers reduce the need for expensive components and intricate assembly processes.

This approach doesn’t mean sacrificing quality. Instead, it emphasizes thoughtful engineering that prioritizes value for the user. At Robobionics, we continually refine our designs to balance simplicity, functionality, and affordability.

Local Manufacturing: Reducing Costs Through Proximity

Producing bionic arms locally, rather than importing them, can significantly reduce costs. Local manufacturing eliminates high shipping fees, import taxes, and delays associated with international supply chains.

In addition to cost savings, local production also allows for faster customization and service. Users can receive tailored adjustments or repairs more quickly, improving their overall experience.

Robobionics champions the “Make in India” initiative, ensuring that our bionic arms are designed and manufactured locally. This not only supports the domestic economy but also makes high-quality prosthetics more accessible to users across India.

The Economics of Local Manufacturing

One of the most immediate advantages of local manufacturing is the reduction in transportation and importation costs. When prosthetic components are produced close to the market they serve, businesses save on shipping fees, customs duties, and storage expenses.

Additionally, local manufacturing reduces the impact of currency fluctuations and international trade restrictions, providing businesses with greater financial stability. These savings can be directly passed on to users, making bionic arms more affordable without compromising on quality.

Faster Turnaround Times

Manufacturing locally accelerates the production and distribution process. This is particularly critical in prosthetics, where customization plays a central role. With local facilities, businesses can respond to user requirements more quickly, from initial fittings to final adjustments.

Rapid production also enables businesses to scale efficiently. Instead of waiting for international shipments, manufacturers can produce and deliver bionic arms within days, ensuring that users receive their devices when they need them most.

For businesses, this speed not only enhances user satisfaction but also allows for quicker feedback loops. By incorporating real-time user feedback into the manufacturing process, companies can continuously refine their products and address issues proactively.

Customization for Local Needs

Different regions have unique requirements for prosthetics based on climate, cultural preferences, and user demographics. Local manufacturing enables businesses to adapt their designs and materials to meet these specific needs effectively.

For example, in humid climates, materials resistant to moisture and corrosion are essential. Local production facilities can experiment with and incorporate these materials into designs more efficiently than distant manufacturers.

Similarly, cultural preferences, such as aesthetic designs or color choices, can be catered to with greater precision when production is localized.

This customization not only improves the usability and acceptance of bionic arms but also strengthens the connection between the business and its community. Users are more likely to trust and recommend products that feel tailored to their needs.

Empowering the Local Workforce

Local manufacturing does more than reduce costs; it creates jobs and builds expertise within the community.

Training local workers in advanced manufacturing techniques, such as 3D printing or CNC machining, not only supports the business but also contributes to regional economic growth.

By investing in workforce development, businesses foster a sense of ownership and pride among employees. A skilled workforce is also more agile, capable of adapting to technological advancements and producing high-quality products that meet global standards.

For businesses, this translates into long-term benefits. A dedicated and skilled local workforce enhances operational efficiency, reduces turnover, and fosters innovation.

Enhancing Repair and Maintenance Services

One of the often-overlooked advantages of local manufacturing is the ability to provide timely repair and maintenance services. Prosthetic devices, including bionic arms, require regular upkeep to maintain functionality.

With local facilities, businesses can establish service centers that handle repairs and replacements quickly. This minimizes downtime for users and ensures that minor issues don’t escalate into major problems.

Additionally, businesses can use these centers to offer training sessions for users and clinicians, further enhancing the overall user experience. This commitment to after-sales support builds trust and encourages repeat business.

Sustainability Through Local Production

Sustainability is an increasingly important consideration in manufacturing. Local production aligns with eco-friendly practices by reducing the carbon footprint associated with long-distance shipping and minimizing waste through efficient supply chains.

Businesses can further enhance sustainability by sourcing materials locally, reducing reliance on imported resources. This not only supports the regional economy but also allows for greater control over the environmental impact of production processes.

By emphasizing sustainability in local manufacturing efforts, businesses can attract environmentally conscious users and differentiate their brand in the market.

Partnerships for Affordable Distribution

Collaborations between prosthetic manufacturers, non-profit organizations, and government programs play a vital role in making bionic arms affordable.

Subsidies, grants, and insurance partnerships can help offset costs for users who cannot afford the full price of a prosthetic device.

Collaborations with Healthcare Providers

Healthcare providers serve as the first point of contact for many individuals seeking prosthetics. Partnering with hospitals, clinics, and rehabilitation centers ensures that bionic arms are integrated into existing care pathways.

These collaborations make distribution seamless and efficient, while also providing users with the clinical support they need.

By working closely with healthcare providers, businesses can gain valuable insights into user needs and refine their offerings.

For example, clinicians can offer feedback on the design and functionality of bionic arms, helping manufacturers create devices that align with medical best practices.

Leveraging Non-Profit Organizations

Non-profit organizations, particularly those focused on healthcare or disability advocacy, are crucial allies in the distribution of affordable bionic arms.

These organizations often have access to underserved communities and can act as intermediaries to deliver prosthetics where traditional market mechanisms might fall short.

By collaborating with non-profits, businesses can participate in subsidized distribution programs or donation drives that make bionic arms accessible to users with limited financial resources.

These partnerships also enhance corporate social responsibility (CSR) initiatives, strengthening the company’s reputation as a socially conscious organization.

Partnering with Government Programs

Governments play a pivotal role in making medical devices affordable through policies, subsidies, and healthcare schemes.

Partnering with government programs can unlock funding opportunities and create streamlined distribution channels for bionic arms.

Businesses can work with government agencies to include their prosthetic devices in national health insurance plans or public healthcare initiatives.

These partnerships ensure that users can access bionic arms at little to no cost, significantly increasing adoption rates.

Collaboration with Insurance Providers

Insurance coverage is a critical factor in making bionic arms affordable for a wide range of users. By partnering with insurance companies, businesses can develop tailored coverage plans that reduce out-of-pocket expenses for users.

These collaborations require clear communication about the value and functionality of bionic arms.

Demonstrating the long-term benefits of advanced prosthetics, such as improved quality of life and reduced dependency on caregivers, can encourage insurance providers to include these devices in their coverage options.

The Impact of Affordable Bionic Arms on Users

Affordable bionic arms are more than just medical devices—they are tools for transformation. When cost is no longer a barrier, users experience profound changes in their physical abilities, mental well-being, and social engagement.

Restoring Independence

For individuals with limb loss, a functional bionic arm can restore the ability to perform daily tasks such as eating, dressing, or driving. These seemingly simple activities often form the foundation of self-reliance and dignity.

An affordable bionic arm enables users to reclaim their independence without enduring financial hardship.

Boosting Confidence and Emotional Health

The psychological benefits of a well-designed bionic arm are immense. Advanced prosthetics that look and function naturally help users feel confident in social and professional settings.

Affordable access to such devices ensures that more individuals can experience this renewed sense of self-esteem.

Technologies Driving Affordability

Innovation in technology continues to drive down the cost of bionic arms while improving their quality. Businesses that embrace these advancements can remain competitive and deliver greater value to their users.

AI and Machine Learning for Smarter Prosthetics

Artificial Intelligence (AI) is no longer exclusive to high-end devices. Affordable bionic arms are now incorporating AI to enable intuitive control. Machine learning algorithms allow prosthetics to learn and adapt to a user’s specific movements and preferences over time.

By using cost-effective sensors and streamlined software, businesses can integrate AI features into entry-level models without significantly increasing production costs. AI also opens the door for remote diagnostics, allowing users to receive technical support without visiting a clinic.

Battery Technology Advancements

Battery life and performance are critical in bionic arms, particularly for users who rely on their prosthetics throughout the day. The development of compact, energy-efficient batteries has reduced the cost of powering bionic arms. For businesses, investing in partnerships with battery manufacturers can further enhance affordability while maintaining long-lasting performance.

User-Centric Design as a Cost-Efficiency Strategy

Designing with the user in mind is not just good practice—it’s a cost-saving strategy. By prioritizing features that users value most, businesses can eliminate unnecessary complexity and focus on delivering high-impact functionality.

Listening to User Feedback

Gathering feedback from prosthetic users helps businesses understand their needs and refine their designs. For instance, a survey may reveal that users prioritize lightweight designs and intuitive controls over additional advanced features.

This information can guide product development, ensuring resources are allocated to the areas that matter most.

Ergonomic and Lightweight Designs

A bionic arm that feels natural to wear is more likely to be adopted by users. Materials like carbon fiber and advanced plastics offer strength and durability while minimizing weight. ‘

By incorporating such materials, manufacturers can enhance comfort and reduce the need for expensive reinforcements.

The Role of Gamified Rehabilitation

Affordable bionic arms are most effective when paired with proper training and rehabilitation programs.

Gamified rehabilitation, which uses game-like exercises to improve motor skills, is an innovative approach that enhances user engagement.

Making Rehabilitation Accessible

Gamified programs can be delivered through mobile apps or home-based systems, reducing the need for frequent clinic visits. Businesses can partner with developers to create cost-effective rehabilitation platforms tailored to their devices.

Increasing User Adaptability

The more intuitive a bionic arm feels, the faster users adapt. Gamified rehabilitation helps users develop muscle memory and confidence in operating their prosthetics. For businesses, this means fewer returns and higher user satisfaction rates.

Sustainability and Affordability: A Winning Combination

Sustainability is becoming an essential consideration in the prosthetics industry. By adopting eco-friendly practices, businesses can not only reduce their environmental impact but also achieve cost efficiencies.

Recyclable Materials

Using recyclable materials in bionic arms reduces manufacturing costs over the long term. Components made from recycled plastics or metals are often cheaper to produce and align with the values of environmentally conscious users.

Circular Economy Models

Businesses can implement programs that allow users to return old prosthetic parts for refurbishing or recycling. This approach lowers production costs and fosters customer loyalty by offering discounts or incentives for participation.

Expanding Access Through Education

Awareness and education are key to making affordable bionic arms accessible to those who need them most. Many individuals remain unaware of the options available or assume that advanced prosthetics are out of their financial reach.

Informative Outreach

Businesses can conduct workshops, webinars, or social media campaigns to educate potential users and healthcare professionals about the benefits and affordability of modern bionic arms.

Clear and transparent information builds trust and helps users make informed decisions.

Collaborating with Clinics

Prosthetic clinics serve as the bridge between manufacturers and users. By training clinicians on the features and benefits of affordable bionic arms, businesses can ensure that their products are effectively recommended and fitted.

The Future of Affordable Bionic Arms

As technology continues to advance, the dream of making bionic arms affordable for everyone is becoming a reality.

The integration of AI, modular designs, 3D printing, and sustainable practices is driving down costs while improving quality.

For businesses, this represents a tremendous opportunity to not only grow but also make a meaningful impact on the lives of millions.

By focusing on innovation, partnerships, and user-centric design, manufacturers can lead the way in creating a future where no one is left behind due to cost constraints.

Conclusion

Affordable bionic arms are not just about technology—they are about transforming lives. By bridging the gap between cost and innovation, we can ensure that these life-changing devices are accessible to everyone who needs them.

Whether through 3D printing, modular systems, or partnerships with clinics and organizations, the path to affordability lies in innovation and collaboration.

For businesses, the mission is clear: to create solutions that balance quality and cost without compromising on user needs.

By embracing user-centric designs, sustainable practices, and cutting-edge technologies like AI, we can redefine what’s possible in prosthetic care.