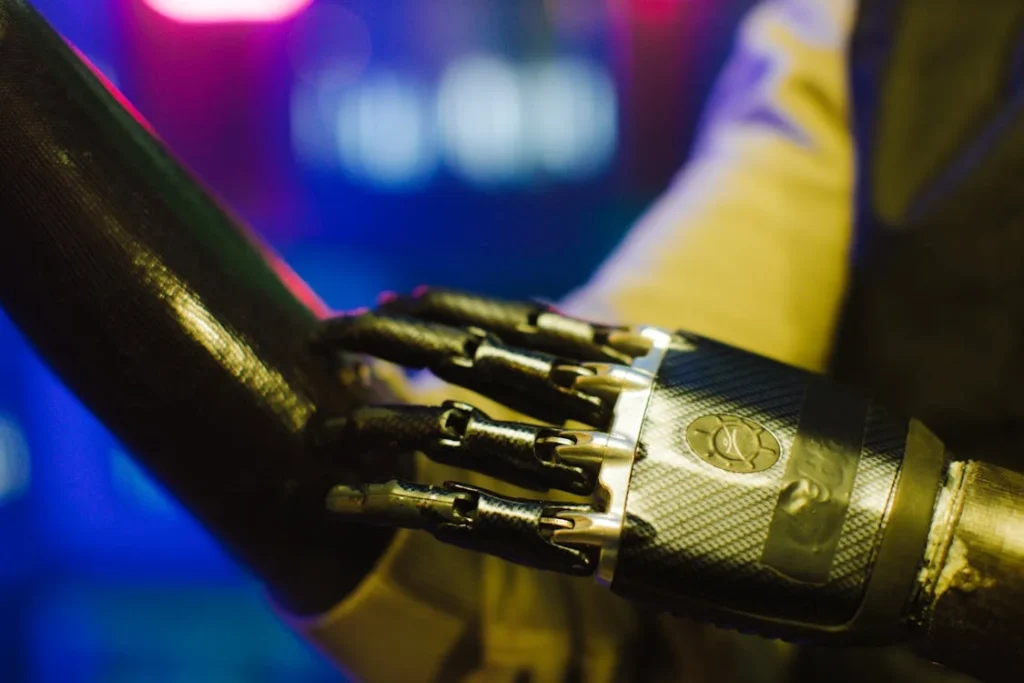

The world of prosthetics is evolving rapidly, with bionic hands and myoelectric prosthetics becoming more advanced than ever before. In 2024, cutting-edge technologies are making artificial limbs more intuitive, responsive, and natural, helping individuals regain independence and control over their daily lives.

For those who rely on a prosthetic limb, improvements in sensor technology, artificial intelligence, and material design are transforming the experience. New innovations allow users to perform precise movements, experience improved grip strength, and even regain a sense of touch. These advancements are not just about function—they are about making prosthetic hands feel like a true extension of the body.

This article explores the latest breakthroughs in bionic hands and myoelectric prosthetics, highlighting how these innovations are shaping the future of prosthetic technology. Whether you are considering a new prosthetic or looking for an upgrade, understanding the latest developments can help you make the best choice for your needs.

Smarter and More Intuitive Myoelectric Control

One of the biggest advancements in myoelectric prosthetics is the improvement in how these devices interpret muscle signals.

Traditional myoelectric hands rely on sensors that detect electrical activity from the user’s muscles.

While effective, these sensors sometimes require a learning curve, as users must train their muscles to send the correct signals.

In 2024, more refined machine learning algorithms are enhancing how myoelectric prosthetics interpret muscle movement.

Instead of requiring users to consciously activate certain muscles, modern bionic hands can predict intended motions based on subtle muscle contractions.

This creates a smoother and more intuitive user experience, allowing for natural hand movements with minimal effort.

Some of the newest myoelectric hands also feature adaptive grip patterns, meaning they can automatically adjust their grip strength based on the object being held.

If a user picks up a fragile glass, the prosthetic senses the resistance and reduces pressure to prevent breakage.

If a heavier object is lifted, the grip tightens accordingly, improving functionality without requiring manual adjustments.

Enhancing Dexterity and Grip Strength in Bionic Hands

Myoelectric prosthetic hands have always been designed to restore basic hand function, but in 2024, the focus has shifted toward increasing dexterity, improving grip strength, and making movements more fluid.

The ability to perform fine motor tasks—like tying shoelaces, using chopsticks, or handling delicate objects—has historically been a challenge for prosthetic users.

New advancements are overcoming these limitations, making bionic hands more responsive and capable of performing complex movements with greater ease.

Multi-Grip Functionality for More Natural Movement

One of the most significant improvements in bionic hands this year is the expansion of multi-grip functionality.

Older myoelectric prosthetics had a limited range of movement, often restricted to basic opening and closing motions.

In contrast, the latest models feature multiple grip modes that mimic the way a natural hand moves.

For instance, modern myoelectric hands now include a tripod grip, which allows users to hold small objects like a pen or a key with precision.

The pinch grip enables delicate handling, making it easier to grasp fragile items without dropping them.

A power grip, on the other hand, is used for lifting heavier objects, ensuring that the prosthetic can handle more demanding tasks.

With these expanded grip patterns, users can perform a wider range of activities without struggling to control their prosthetic hand manually.

The transition between different grip modes has also become more seamless. Some of the latest bionic hands now feature automatic grip switching, where the prosthetic detects the shape and weight of an object and adjusts its grip accordingly.

This reduces the need for users to manually select a grip pattern, making everyday tasks more effortless.

Stronger and More Durable Motors for Better Grip Strength

Grip strength is another area where significant progress has been made.

Early myoelectric prosthetics sometimes lacked the power to firmly hold onto objects, making it difficult to carry heavier items.

In 2024, stronger and more efficient motors are allowing prosthetic users to apply greater force when gripping.

These new motors use advanced torque control to regulate grip strength in real time.

If a user picks up a water bottle, the prosthetic hand applies just enough force to hold it securely without crushing it.

If they attempt to carry a bag of groceries, the hand can automatically adjust to grip the handles tightly, preventing accidental slips.

In addition to stronger grip forces, modern myoelectric hands are also faster in response time.

This means users no longer experience delays between thinking about a movement and the prosthetic executing it.

The latest myoelectric control systems can process muscle signals in milliseconds, allowing for nearly instantaneous reaction times.

This improvement makes a big difference in day-to-day activities, as it reduces the lag between intention and action.

Anti-Slip Technology for a More Secure Grip

Another key improvement in 2024 is the integration of anti-slip technology into prosthetic hand designs.

One of the common challenges users face is accidentally dropping objects due to inconsistent grip pressure.

To address this, some of the newest bionic hands now include sensor-driven grip adjustments.

These sensors continuously monitor how much force is being applied to an object and make real-time corrections if the grip starts to weaken.

For example, if a user is holding a smartphone, the prosthetic hand will detect even the slightest movement or slippage and immediately adjust its grip to keep the phone secure.

This technology helps users feel more confident when handling valuable or delicate items, as it greatly reduces the risk of accidental drops.

The Integration of Sensory Feedback: Restoring the Sense of Touch

One of the most groundbreaking advancements in myoelectric prosthetics is the development of sensory feedback technology.

For decades, prosthetic hands have focused solely on movement and grip strength, but without the ability to feel objects, users had to rely on visual cues to judge pressure and positioning.

In 2024, new innovations are bringing a sense of touch back to prosthetic users, making artificial limbs more intuitive and natural than ever before.

How Sensory Feedback Works in Bionic Hands

Sensory feedback technology allows prosthetic hands to send real-time information about touch, pressure, and texture back to the user’s nervous system.

This is achieved through small sensors embedded in the fingers and palm of the prosthetic.

These sensors detect various levels of pressure and translate them into electrical signals, which are then transmitted to the user’s skin or nerves through vibrations or electrical stimulation.

For instance, when holding a soft object like a sponge, the sensors recognize the light pressure and relay that information, helping the user understand how firmly they are gripping it.

If the user picks up something heavier, the system sends a stronger signal, letting them know they need to apply more force.

This real-time feedback allows for better control, reducing the likelihood of dropping or crushing objects.

Advancements in Neural Interfaces for Direct Sensation

The latest research in prosthetic technology is now focusing on neural interfaces, which allow bionic hands to connect directly to the nervous system.

Unlike traditional vibration-based feedback systems, these interfaces send electrical impulses directly to the nerves, creating a more natural feeling of touch.

This means users can “feel” objects as if they were touching them with a biological hand.

In early clinical trials, individuals using neural-integrated prosthetics reported being able to distinguish between different textures, such as rough and smooth surfaces.

Some even described the sensation as nearly identical to natural touch. While this technology is still being refined, the rapid progress suggests that fully sensory-enabled prosthetics could become widely available in the near future.

The Benefits of Sensory Feedback for Everyday Use

Sensory feedback is not just about making prosthetics feel more natural—it also has real-world benefits that improve usability.

One of the biggest challenges for prosthetic users has always been controlling grip force.

Without sensation, it is easy to apply too much or too little pressure, leading to accidents.

With feedback technology, users no longer have to guess how hard they are gripping objects, significantly reducing errors.

Another advantage is improved balance and coordination. When we use our hands, we unconsciously adjust our grip and positioning based on touch.

Sensory feedback restores this ability in prosthetic users, allowing for smoother, more controlled movements.

Tasks like buttoning a shirt, holding a glass, or typing on a keyboard become much easier when users can rely on touch rather than sight alone.

These advancements in sensory feedback are a major step toward creating prosthetic limbs that feel like real extensions of the body.

As technology continues to develop, users can expect even more lifelike and responsive bionic hands in the years to come.

Artificial Intelligence and Machine Learning in Myoelectric Prosthetics

In 2024, artificial intelligence (AI) and machine learning are playing a crucial role in making myoelectric prosthetics smarter, more adaptable, and easier to use.

Traditional prosthetics require users to learn how to control them, but with AI-driven systems, the prosthetic learns from the user instead.

This shift in technology is making bionic hands more responsive, intuitive, and personalized than ever before.

Adaptive Learning for More Natural Movements

One of the biggest challenges for prosthetic users has always been training their muscles to communicate with their device.

In the past, myoelectric prosthetics required users to send precise muscle signals to activate different grips or movements.

If the signals weren’t strong enough or consistent, the prosthetic would not respond correctly.

AI is now solving this problem by allowing prosthetics to learn from the user’s natural movements.

Modern AI-driven myoelectric hands continuously analyze muscle activity, detecting patterns and predicting intended actions.

Instead of requiring perfect muscle contractions, the prosthetic adjusts itself over time, making movements more fluid and natural.

This means that even if a user’s muscle strength changes throughout the day due to fatigue or activity, the prosthetic will adapt and respond accordingly.

Predictive Motion Technology for Faster Response

Another breakthrough in AI-powered prosthetics is predictive motion technology.

By analyzing past movements and muscle signals, these prosthetics can anticipate what action the user is about to perform before they even complete the motion.

This reduces lag time between intention and action, making movements feel more immediate and lifelike.

For example, if a user frequently switches between a pinch grip and a power grip while performing a task, the prosthetic will recognize this pattern and automatically adjust its grip transition speed.

Over time, the prosthetic refines its responses, making everyday activities smoother and less mentally demanding.

Voice and Gesture Control for Hands-Free Operation

Some of the newest prosthetic models are incorporating alternative control methods, such as voice and gesture recognition.

Users can now program their prosthetic hands to respond to spoken commands, such as “open hand” or “switch to tripod grip,” making it easier to change functions without relying solely on muscle signals.

Additionally, gesture-based controls allow users to move their prosthetic by simply tilting their residual limb or making small, intentional movements.

This feature is particularly beneficial for individuals with limited muscle control, providing an additional way to interact with their prosthetic hand.

AI-Powered Customization and Smart Adjustments

AI is also making prosthetics more personalized. Many new myoelectric hands come with mobile apps that allow users to fine-tune their prosthetic’s settings.

Through these apps, users can customize grip strength, sensitivity, and movement speed based on their preferences and activities.

Some systems even offer real-time feedback, providing suggestions on how to improve control and efficiency.

As AI continues to evolve, prosthetic hands will become even more intelligent, learning from real-world interactions and adapting to each user’s specific needs.

This shift from manually controlled devices to smart, self-learning prosthetics is transforming the way users experience and interact with their artificial limbs.

The Role of 3D Printing in the Next Generation of Bionic Hands

The use of 3D printing in prosthetic design has revolutionized the industry, making bionic hands more accessible, affordable, and customizable.

In 2024, advancements in 3D printing technology are allowing for stronger, lighter, and more personalized prosthetic hands that better fit the needs of individual users.

This innovation is transforming the way prosthetics are manufactured, reducing costs and increasing the speed of production while maintaining high-quality performance.

Customization for a Perfect Fit

A major challenge with traditional prosthetics has been achieving a perfect fit for each user.

Since every individual has a unique residual limb shape, creating a socket that provides both comfort and stability has often required multiple adjustments and expensive custom molding.

With 3D scanning and printing, prosthetists can now design and produce personalized sockets that match the exact contours of the user’s limb.

By using advanced digital modeling, a prosthetic hand can be tailored in terms of size, weight distribution, and grip strength to suit an individual’s specific lifestyle and needs.

This ensures better comfort, reduces pressure points, and improves the overall experience of using a prosthetic for extended periods.

Lighter and Stronger Materials for Better Performance

Early prosthetic hands were often bulky and heavy, making them uncomfortable for all-day wear.

The latest developments in 3D printing now allow for the use of advanced lightweight materials, such as carbon fiber composites and high-strength polymers, which reduce weight while maintaining durability.

These materials not only improve comfort but also enhance prosthetic performance. A lighter hand reduces fatigue, allowing users to perform daily activities with greater ease.

Additionally, stronger materials ensure that the prosthetic can withstand repeated use without damage, extending its lifespan and reducing the need for frequent replacements.

Faster and More Affordable Production

Traditional prosthetic manufacturing is a time-consuming and expensive process, requiring complex molds and lengthy fabrication periods.

With 3D printing, prosthetic hands can be produced much faster and at a lower cost.

In some cases, a fully functional prosthetic can be printed and assembled in a matter of days, making it easier for users to receive their prosthetic quickly without long waiting times.

This is particularly beneficial for children, who frequently outgrow their prosthetics and require replacements.

Instead of going through a costly and lengthy refitting process, a new, properly sized prosthetic can be 3D-printed at a fraction of the time and cost.

The Future of Fully Bionic 3D-Printed Hands

The integration of electronics and 3D-printed components is advancing rapidly.

Some of the latest research focuses on embedding sensors and soft actuators directly into 3D-printed prosthetic hands, allowing for more flexible movement and enhanced sensory feedback.

The goal is to create prosthetics that are not only highly functional but also visually appealing, durable, and seamlessly integrated with modern technology.

At Robobionics, we embrace these advancements, using cutting-edge 3D printing techniques to produce high-quality prosthetic solutions that are customized for each user.

By combining precision engineering with innovative materials, we ensure that our bionic hands are designed for both performance and comfort.

The Growing Role of Battery Efficiency and Power Management in Myoelectric Prosthetics

One of the biggest challenges in myoelectric prosthetics has always been battery life.

Unlike body-powered prosthetics, which rely on mechanical force, myoelectric hands need a constant power source to operate their motors, sensors, and processors.

In 2024, advancements in battery efficiency and power management are addressing this issue, making prosthetic hands last longer, charge faster, and operate more reliably throughout the day.

Extended Battery Life for All-Day Use

Early myoelectric prosthetics often required frequent recharging, sometimes leaving users without function when they needed it most.

New battery technologies are significantly improving energy efficiency, allowing users to go longer between charges.

The latest lithium-ion and graphene-based batteries can now hold a charge for an entire day, even with frequent use.

These modern batteries also support smart power distribution, meaning energy is allocated more efficiently depending on the type of movement being performed.

For instance, delicate grips require less power than a strong hold, so the system automatically adjusts power output to maximize battery life.

This feature ensures that the prosthetic does not drain energy unnecessarily, keeping it running smoothly for extended periods.

Fast Charging and Wireless Power Solutions

Recharging a prosthetic hand used to be a time-consuming process, often requiring hours of downtime.

The latest advancements in charging technology now allow for much faster recharge times.

Some of the newest myoelectric hands can reach 80% battery capacity in under an hour, ensuring minimal disruption to daily life.

Wireless charging is also becoming a reality for prosthetic users. Instead of needing to remove and plug in their prosthetic, users can simply place their hand on a charging pad or use portable wireless charging solutions.

This innovation is particularly beneficial for individuals with limited mobility, as it removes the need for manual handling of cables and connectors.

Energy Harvesting for Sustainable Power

One of the most exciting developments in myoelectric prosthetic technology is energy harvesting.

This emerging field focuses on generating power from the user’s body movements or surrounding environment.

Researchers are exploring ways to integrate kinetic energy systems that convert motion into electricity, allowing the prosthetic to recharge itself while in use.

For example, small generators inside the prosthetic could capture energy from hand and arm movements, continuously supplying power throughout the day.

Another approach involves thermoelectric charging, which uses body heat to generate electricity.

While these technologies are still in development, they have the potential to significantly reduce the need for external charging and improve long-term usability.

Smart Battery Monitoring for Better User Control

Modern prosthetic hands are now equipped with battery monitoring systems that give real-time feedback on power levels.

Through mobile apps or built-in displays, users can track their battery status and receive alerts when it’s time to recharge.

Some systems even offer predictive alerts, notifying users in advance if battery life is running low based on their daily usage patterns.

These innovations in battery efficiency, fast charging, and smart power management are making myoelectric prosthetics more reliable and user-friendly than ever before.

With longer-lasting power and seamless charging options, users can focus more on living their lives and less on worrying about battery limitations.

Conclusion

The latest advances in bionic hands and myoelectric prosthetics are transforming the way users experience artificial limbs. With smarter muscle control, sensory feedback, AI-driven adaptability, and sleek, customizable designs, prosthetic hands are becoming more natural, intuitive, and personalized than ever before. These innovations are not just improving function—they are restoring confidence, independence, and quality of life.

Technology is moving toward prosthetics that feel like a true extension of the body. Features such as adaptive grip strength, real-time sensory feedback, and wireless power management are making prosthetic hands more user-friendly and efficient. Customization and aesthetic choices also allow users to embrace their prosthetic as a reflection of their personal style and identity.

At Robobionics, we are committed to delivering the most advanced, comfortable, and functional prosthetic solutions available. As technology continues to evolve, so will our dedication to improving the lives of those who rely on prosthetic hands. If you’re ready to explore the next generation of bionic hands, book a consultation today and take the first step toward a more empowered future.